3D Printing: The Ultimate Guide to Additive Manufacturing

- shiva ganesh

- Jul 31

- 4 min read

Table of Contents

Introduction to 3D Printing

What is 3D Printing?

3D Printing, also known as Additive Manufacturing (AM), is a process of creating three-dimensional solid objects directly from digital models by layering materials. Unlike subtractive methods like CNC machining, 3D printing builds parts layer-by-layer, enabling the creation of complex geometries with minimal waste.

Whether it’s prototyping medical devices, aerospace parts, or architectural models, 3D printing offers unmatched flexibility and customization.

A Brief History of 3D Printing Technology

The roots of 3D printing date back to the 1980s with the invention of stereolithography (SLA). Over the decades, advancements like Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS) have broadened its applications. Today, 3D printing is revolutionizing industries with rapid prototyping, lightweight components, and even bio-printing.

How 3D Printing Works

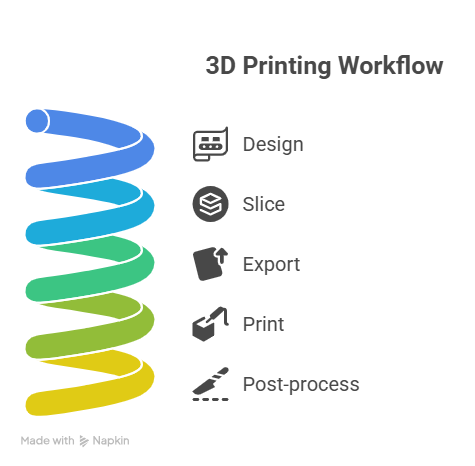

The Basic Workflow

Think of it as assembling something from the ground up, layer by layer:

Design the object using CAD software.

Slice the model into thin layers via slicing software.

Export the file (usually as .STL or .OBJ) and load it into the 3D printer.

Print the object as the printer lays down material layer-by-layer.

Post-process the part (cleaning, curing, smoothing).

Key Components of 3D Printers

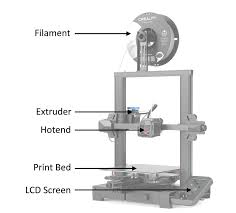

Print Head / Extruder / Laser

The mechanism responsible for depositing or solidifying the material, whether by extruding filament or sintering powder.

Build Platform / Print Bed

The surface where the object is constructed layer by layer.

Control System

Interprets the sliced model and governs movement, temperature, and material flow.

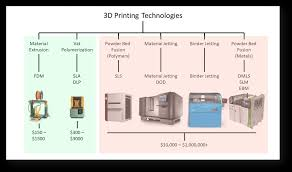

Types of 3D Printers

FDM (Fused Deposition Modeling)

The most common type for hobbyists and industry alike. Melts thermoplastic filaments and deposits them layer by layer.

SLA (Stereolithography)

Uses UV light to solidify liquid resin. Known for high accuracy and smooth surfaces.

SLS (Selective Laser Sintering)

Uses lasers to fuse powdered material. Ideal for complex geometries and functional parts.

DMLS (Direct Metal Laser Sintering)

A metal 3D printing process using laser fusion. Widely used in aerospace and medical industries.

Multi-Jet Fusion / PolyJet

Sprays droplets of material and cures them with light. Capable of highly detailed, multi-material prints.

3D Printing Processes

Extrusion-based (FDM)

Melts and extrudes thermoplastic through a nozzle to build objects layer-by-layer.

Vat Photopolymerization (SLA/DLP)

Solidifies resin in a vat using light, layer-by-layer.

Powder Bed Fusion (SLS/DMLS)

Uses heat to fuse powdered materials together selectively.

Material Jetting

Similar to inkjet printing but deposits build and support materials simultaneously.

3D Printing Software

What is Slicing Software?

Slicing software converts 3D CAD models into layer instructions for the printer.

Popular CAD & Slicing Tools:

Fusion 360

SolidWorks

Ultimaker Cura

PrusaSlicer

Autodesk Netfabb

Materials Used in 3D Printing

Polymers

PLA

ABS

PETG

Nylon

TPU (Flexible)

Metals

Stainless Steel

Titanium

Aluminum

Inconel

Resins

Standard Resins

Tough Resins

Dental and Bio-Compatible Resins

Composites

Carbon fiber-reinforced

Glass-filled nylon

Applications of 3D Printing

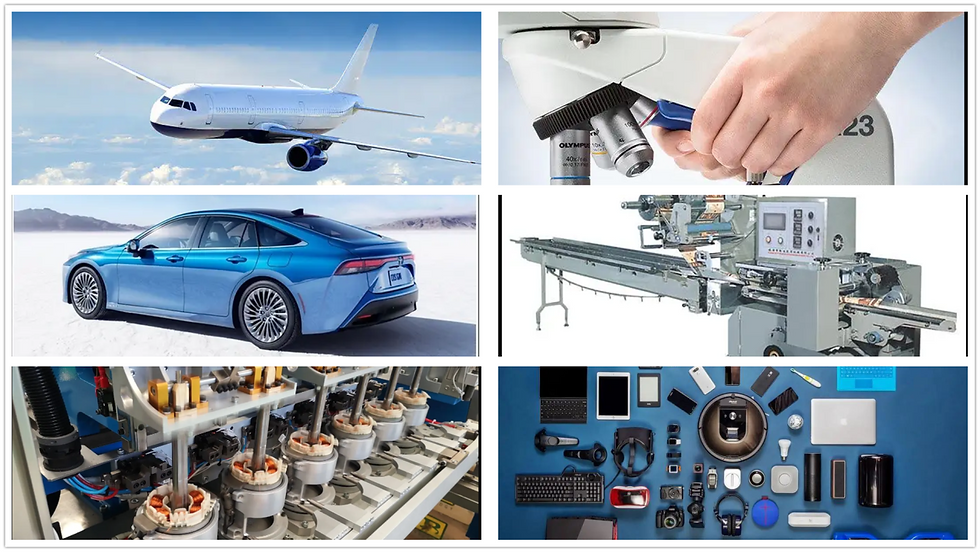

Aerospace

Lightweight, complex geometries for components and tooling.

Automotive

Rapid prototyping, jigs, fixtures, and even end-use parts.

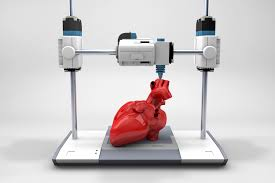

Medical Devices

Custom implants, prosthetics, and surgical planning models.

Consumer Electronics

Casing prototypes, connectors, and lightweight components.

Architecture

Scaled models for visualization and concept presentations.

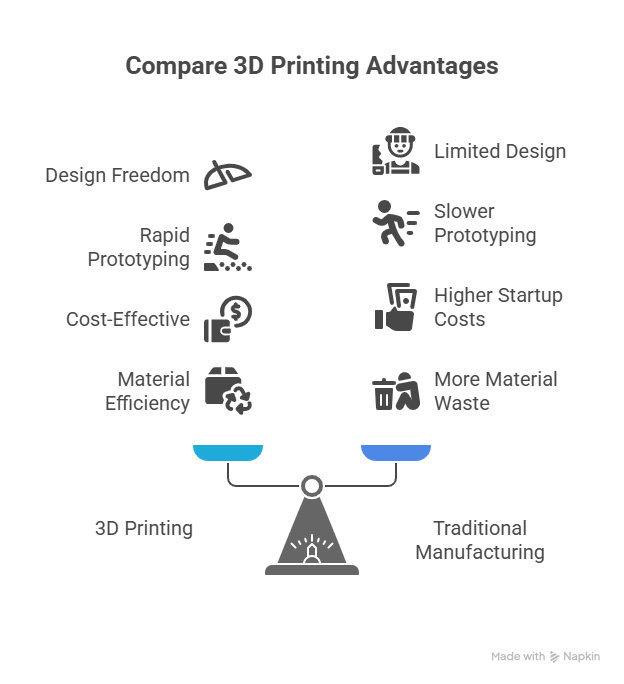

Advantages of 3D Printing

Design Freedom

Create shapes impossible through traditional manufacturing.

Rapid Prototyping

From idea to physical model within hours or days.

Cost-Effective for Low Volumes

No tooling required, reducing startup costs.

Material Efficiency

Minimal waste compared to subtractive methods.

Limitations of 3D Printing

Mechanical Properties

Layer adhesion may result in weaker parts than traditionally manufactured ones.

Surface Finish

Often requires post-processing for smoothness or accuracy.

Speed for Large Parts

Can be slower than CNC or injection molding for large-scale production.

Material Restrictions

Not all materials are suitable for 3D printing.

3D Printing vs. CNC Machining

Key Differences

Feature | 3D Printing | CNC Machining |

Process | Additive | Subtractive |

Ideal Use | Prototypes, Complex Shapes | Functional, Structural Parts |

Material | Mostly Plastics / Some Metals | Mostly Metals |

Speed | Slow per part, fast for iteration | Fast for bulk, slow setup |

When to Choose One Over the Other

3D Printing: Prototyping, intricate designs, small batches.

CNC Machining: Precision, structural integrity, mass production.

Future Trends in 3D Printing

AI & Automation

Automated build farms, AI-generated geometries, and autonomous quality control.

Sustainable Materials

Biodegradable and recyclable materials are on the rise.

Mass Customization

Personalized products at scale through digital manufacturing.

Cost Considerations

Cost of Machines

From ₹30,000 for hobby FDM printers to ₹2 crore+ for industrial metal systems.

Cost of Operation and Maintenance

Includes materials, post-processing tools, software licenses, and maintenance.

Choosing the Right 3D Printer

Based on Material and Application

FDM for functional prototypes

SLA for detailed models

SLS/DMLS for production-grade parts

Based on Production Volume

Low volume: Desktop or benchtop

Medium to high volume: Industrial multi-machine setups

Tips for Getting Started with 3D Printing

Training and Certifications

Online platforms: Coursera, Udemy, LinkedIn Learning

Manufacturer certifications (Stratasys, EOS, etc.)

Recommended Tools and Resources

YouTube Channels: 3D Printing Nerd, Maker’s Muse

Communities: Reddit r/3Dprinting, Prusa forums

Books: "The 3D Printing Handbook" by 3D Hubs

Conclusion

3D printing is redefining how we design, develop, and manufacture. From rapid prototypes to functional parts, it provides unmatched flexibility and creativity. For startups or large-scale industries, 3D printing opens doors to possibilities once thought impossible

Comments