CNC Machining: The Ultimate Guide to Precision Manufacturing

- Bhargava Krishna Marripati

- Jul 23

- 5 min read

Updated: Jul 24

Introduction to CNC Machining

What is CNC Machining?

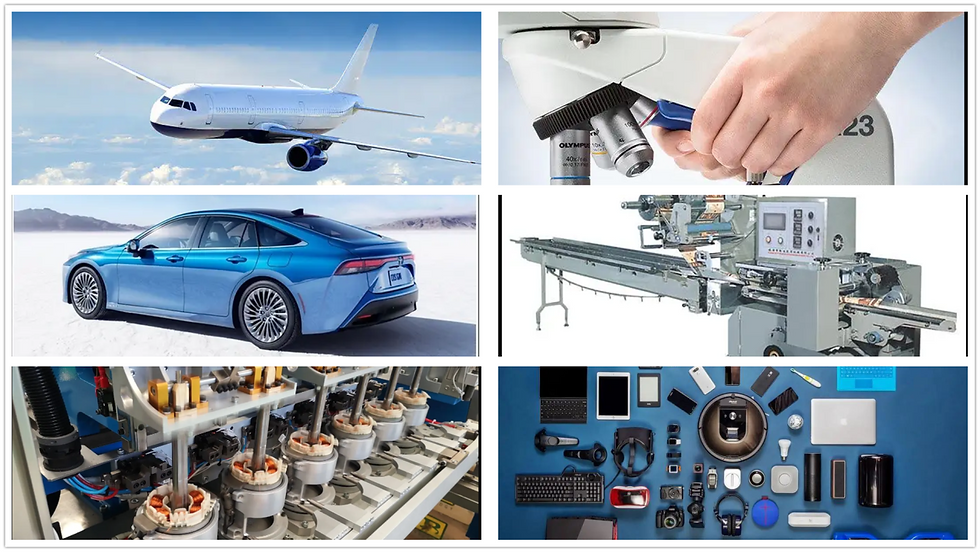

CNC (Computer Numerical Control) Machining is a subtractive manufacturing process that uses computer-controlled tools to shape materials into precise components. Whether you're crafting an airplane wing, a smartphone casing, or a prosthetic limb, CNC machining ensures extreme accuracy, speed, and repeatability.

Table of Contents

A Brief History of CNC Technology

CNC technology traces back to the 1940s when punched tape-controlled machines were first developed. By the 1970s, digital computers took over, and CNC machines began revolutionizing how manufacturers built complex components. Today, CNC machining is the backbone of precision manufacturing.

How CNC Machining Works

The Basic Workflow

Think of it as baking, but with metal and extreme precision. Here's the typical CNC process:

Design the part in CAD software.

Convert the design into G-code via CAM software.

Load the G-code into the CNC machine.

Machine the part by cutting, drilling, or milling the raw material.

Inspect the final piece for quality control.

Key Components of CNC Machines

Controller

The brain of the operation. It interprets G-code and directs the machine’s movements.

Machine Tool

The part that performs the action—cutting, drilling, etc. Common tools include mills, lathes, and drills.

Feedback Systems

These sensors monitor the machine’s position and movements to ensure precision and accuracy.

Types of CNC Machines

CNC Milling Machines

These machines rotate cutting tools and move the workpiece to remove material. Ideal for complex 3D shapes.

CNC Lathes

Perfect for cylindrical parts. The workpiece spins while the tool shapes it.

CNC Routers

Typically used on softer materials like wood, plastic, and aluminum. Think of them as high-speed carving machines.

CNC Plasma Cutters

These cut through metals using a high-powered plasma torch. Great for sheet metal fabrication.

CNC EDM Machines

EDM stands for Electrical Discharge Machining. It’s like sculpting with electricity—used for hard metals and delicate features.

CNC Machining Processes

Milling

Milling machines remove material using rotating multi-point cutting tools. Used for slots, holes, and complex shapes.

Turning

Turning involves spinning the part and cutting along its axis. Ideal for symmetrical shapes like shafts and pins.

Drilling

As simple as it sounds—creating holes with high precision and consistency.

Grinding

Used to achieve high surface finish and tight tolerances by removing small amounts of material.

CNC Programming and G-code

What is G-code?

G-code is the machine language that tells CNC machines where to move, how fast, and what path to follow. It's the roadmap for the whole operation.

CAD and CAM Software

You start with CAD (Computer-Aided Design) to design the part. Then, CAM (Computer-Aided Manufacturing) turns that design into G-code instructions.

Popular software includes:

Fusion 360

SolidWorks

Master cam

AutoCAD

Materials Used in CNC Machining

Metals

Aluminum

Steel

Titanium

Brass

Plastics

ABS

Nylon

PEEK

Polycarbonate

Composites

Carbon fiber-reinforced plastics

Fiberglass

Applications of CNC Machining

Aerospace

Precision and performance—CNC machining delivers parts that meet tight tolerances and high safety standards.

Automotive

From engine blocks to custom exhaust tips, CNC plays a huge role in the car industry.

Medical Devices

Prosthetics, surgical instruments, and implants—reliability is key.

Consumer Electronics

Casings, buttons, heat sinks—everything you touch in a smartphone likely started on a CNC machine.

Advantages of CNC Machining

Precision and Accuracy

Tolerances as tight as ±0.001 mm are achievable—ideal for mission-critical parts.

Repeatability

You can make 10 or 10,000 identical parts with the same quality.

Speed and Efficiency

CNC machines run 24/7 with minimal supervision.

Limitations of CNC Machining

Initial Cost

High setup and machinery costs can be a barrier for small operations.

Complexity in Setup

Programming and fixture setup need skilled technicians.

Material Waste

As a subtractive method, material wastage is more than additive manufacturing.

CNC Machining vs. 3D Printing

Key Differences

Feature | CNC Machining | 3D Printing |

Material | Mostly metals | Mostly plastics |

Speed | Faster for bulk | Slower per part |

Precision | Higher | Lower (in most cases) |

When to Choose One Over the Other

Choose CNC for structural, high-precision, or load-bearing parts. Go with 3D printing for prototypes, complex geometries, or low-volume runs.

Future Trends in CNC Machining

Automation and AI Integration

Smart CNC machines now adapt in real-time, correct tool paths, and predict failures.

Industry 4.0 and Smart Factories

Connected machines sharing data to optimize operations—CNC is at the heart of this evolution.

Cost Considerations

Cost of Machines

Anywhere from ₹5 lakhs to ₹2 crores depending on size and complexity.

Cost of Operation and Maintenance

Energy, tooling, software, and skilled labor all add up—be ready to budget accordingly.

Choosing the Right CNC Machine

Based on Material and Application

Different tools work better for aluminum than for hardened steel. Know your material before choosing your setup.

Based on Production Volume

Small batch = basic 3-axis. Mass production = multi-axis with auto-loading.

Tips for Getting Started with CNC Machining

Training and Certifications

Look for courses in CAD/CAM software, G-code programming, and machine operation.

Recommended Tools and Resources

YouTube channels: NYC CNC, Titans of CNC

Books: “CNC Programming Handbook” by Peter Smid

Forums: Practical Machinist, Reddit’s r/CNC

Conclusion

CNC machining isn’t just about cutting metal—it’s about precision, innovation, and scaling manufacturing to a whole new level. Whether you're launching a startup or upgrading your production line, CNC is the powerhouse that can make it happen.

FAQs

1. What does CNC stand for?

CNC stands for Computer Numerical Control—machines guided by computers to manufacture precision parts.

2. Is CNC machining better than manual machining?

Absolutely. It's faster, more accurate, and can handle complex geometries with consistency.

3. How expensive is a CNC machine?

They can range from ₹5 lakhs for basic desktop units to ₹2 crores for industrial 5-axis models.

4. What industries use CNC the most?

Aerospace, automotive, medical devices, and consumer electronics are top industries relying on CNC.

5. Can I learn CNC machining online?

Yes! Platforms like Coursera, Udemy, and YouTube offer comprehensive beginner-to-advanced CNC courses.

Comments