CNC Turning: Precision Machining for Rotational Parts

- Bhargava Krishna Marripati

- Jul 23

- 5 min read

Updated: Jul 24

Table of content

Introduction to CNC Turning

What is CNC Turning?

CNC Turning is a subtractive machining process where a cutting tool removes material from a rotating workpiece. It’s one of the oldest and most efficient ways to manufacture symmetrical, cylindrical parts—like shafts, screws, nuts, and bushings.

How It Works Compared to Milling

In milling, the cutting tool rotates while the workpiece is fixed. In turning, it’s the opposite—the workpiece rotates, and the cutting tool moves in a linear path to shape it. This makes CNC turning the go-to choice for round parts.

Understanding the CNC Turning Process

The Basics of Rotational Machining

In CNC turning, the material (usually a metal or plastic rod) is clamped into a chuck and spun at high speeds. A stationary tool then removes material along the diameter, creating desired shapes with extreme precision.

Key Movements in a CNC Lathe

Z-Axis: Controls longitudinal movement (in/out).

X-Axis: Controls radial movement (toward/away from center).

Optional Y or C-Axis: For advanced operations like off-center drilling or milling.

Workflow of a CNC Turning Operation

Design in CAD.

Toolpath generation in CAM.

Program the G-code.

Load material and set zero points.

Run the operation and inspect parts.

Types of CNC Turning Machines

Horizontal Turning Centers

The most common type. They’re efficient, versatile, and suitable for everything from prototyping to full-scale production.

Vertical Turning Lathes (VTLs)

Used for heavy, large-diameter workpieces. Gravity helps hold the part in place—ideal for big automotive or aerospace components.

Swiss-Type Lathes

Designed for small, high-precision parts like watch components or medical implants. The material is supported close to the cutting area for minimal deflection.

Multi-Spindle Turning Machines

These machines have multiple spindles working simultaneously—perfect for high-volume production.

CNC Turning Tools

Common Turning Tool Types

External Turning Tools – For shaping outer diameters.

Boring Bars – For enlarging or finishing inner diameters.

Threading Tools – For cutting external and internal threads.

Grooving Tools – For machining narrow slots or reliefs.

Tool Holders and Inserts

Indexable carbide inserts are widely used. They offer long life, quick replacement, and consistent performance.

Tool Maintenance and Wear

Monitoring wear ensures better surface finish and dimensional accuracy. Dull tools lead to heat buildup and poor performance.

CNC Turning Operations

Facing

Creates a flat surface perpendicular to the axis. First operation in many parts.

Turning (Straight & Taper)

Reduces the diameter along the length of the part. Can be done straight or angled (taper).

Boring

Enlarges an existing hole to a precise diameter.

Threading

Cuts screw threads—internal or external—using a threading tool or tap/die.

Grooving

Cuts narrow grooves or reliefs, often used for O-rings or snap rings.

Knurling

Creates patterned textures for grip on knobs, handles, etc.

Materials Suitable for CNC Turning

Metals

Aluminum – Lightweight and easy to machine.

Stainless Steel – Corrosion-resistant and strong.

Brass – Smooth cutting, used in fittings.

Titanium – Strong, light, and corrosion-resistant.

Plastics

Nylon – Tough and flexible.

PTFE (Teflon) – Low friction and chemical resistance.

Delrin (Acetal) – High stiffness and dimensional stability.

Composite and Specialty Materials

Used in aerospace and medical sectors where performance outweighs cost.

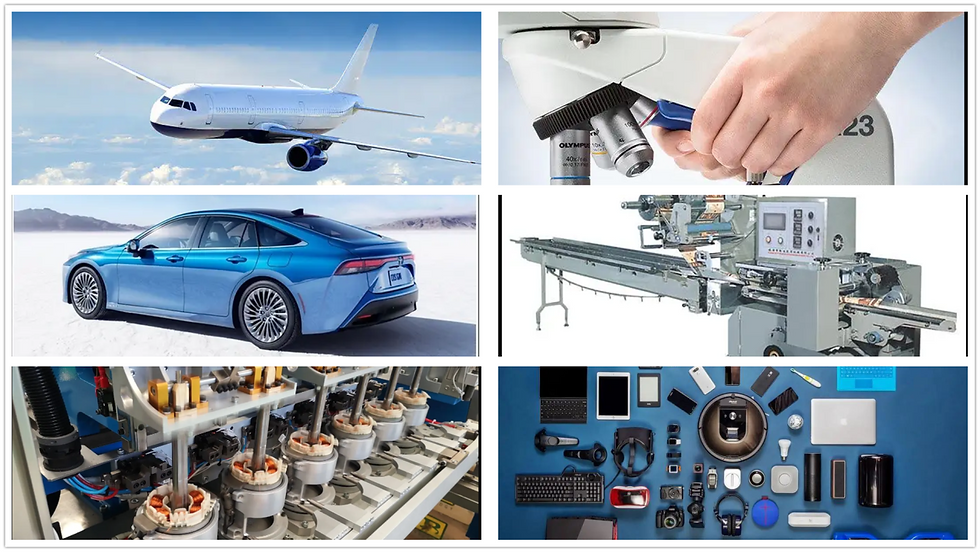

Applications of CNC Turning

Automotive Parts

Axles, shafts, pistons, and engine components rely heavily on turning.

Aerospace Components

Turbine rings, spacers, and connectors—all turned to tight tolerances.

Medical Implants

Orthopedic screws, bone plates, and dental abutments need precise, biocompatible machining.

Hydraulic and Pneumatic Fittings

Connectors, couplings, and adapters require leak-proof, precise machining.

CNC Turning vs. Manual Lathe

Speed and Precision

CNC turning drastically reduces machining time while delivering parts with superior accuracy.

Consistency and Repeatability

Once programmed, a CNC lathe can produce thousands of identical parts with little variation.

Operator Skills and Automation

Manual lathe work is more skill-intensive. CNC lathes, once programmed, require minimal human intervention.

Advantages of CNC Turning

High Accuracy

Modern CNC lathes achieve tolerances as tight as ±0.005 mm.

Efficient for Cylindrical Parts

If it’s round, CNC turning is usually the fastest and most cost-effective solution.

Fast Cycle Times

Ideal for medium to high-volume production.

Limitations of CNC Turning

Geometric Constraints

Non-cylindrical features are difficult to produce—milling or multi-tasking machines may be required.

Limited to Symmetrical Parts

Irregular shapes often require 5-axis milling or hybrid setups.

Setup and Tooling Complexity

Complex parts may require multiple setups or tools.

Software and Programming in Turning

G-code in Turning

G-code commands include tool movements, spindle speeds, and tool changes. Example:G01 X30 Z-20 F0.2 – Move to X30, Z-20 at feed rate of 0.2 mm/rev.

CAM Software for Turning

Popular programs:

Fusion 360

Master cam

Solid CAM

Toolpath Optimization

Efficient toolpaths reduce cycle time, tool wear, and energy consumption.

Innovations and Trends in CNC Turning

Live Tooling

Allows milling, drilling, and tapping operations on a lathe—transforming it into a multi-process workstation.

Multi-Axis Lathes

Machines with Y-axis or B-axis enhance capability to produce complex geometries.

Smart Sensors and Predictive Analytics

Modern CNC lathes monitor vibrations, loads, and temperatures to prevent breakdowns and extend tool life.

Choosing the Right CNC Lathe

Based on Part Geometry

Simple parts = 2-axis lathe; Complex features = Multi-axis with live tooling.

Based on Production Volume

Prototypes = Basic lathe; Mass production = Multi-spindle or bar-fed Swiss-type lathe.

Budget Considerations

Entry-level: ₹5–10 lakhs Advanced multi-axis machines: ₹50 lakhs+

Getting Started with CNC Turning

Basic Skills and Training

Learning G-code, tool setup, and safety is essential. Many online platforms offer beginner-friendly courses.

Affordable Entry-Level Machines

Brands like Tormach and Grizzly offer compact CNC lathes ideal for small shops and startups.

Common Mistakes to Avoid

Incorrect tool offsets

Overlooking chip evacuation

Not accounting for tool deflection

Conclusion

CNC turning remains one of the most reliable and efficient ways to produce round, precise components in today’s fast-paced manufacturing world. With advancements like live tooling and automation, it continues to evolve—making it a must-have process in any modern machining setup.

FAQs

1. What is the difference between CNC turning and CNC milling?

Turning rotates the workpiece; milling rotates the tool. Turning is ideal for cylindrical parts.

2. What are the main advantages of CNC turning?

High precision, repeatability, and fast cycle times for round components.

3. Can CNC turning be used on plastic materials?

Yes! Materials like PTFE, nylon, and Delrin are commonly turned with excellent results.

4. What industries rely most on CNC turning?

Automotive, aerospace, medical, and hydraulic/pneumatic manufacturing.

5. How do I get started with CNC turning?

Start with online courses, a basic CNC lathe, and small projects to build confidence and skill.

Comments