Insert Molding: A Complete Guide to Advanced Manufacturing

- Bhavana Maram

- Aug 1

- 4 min read

Table Of Contents

Insert Molding: A Complete Guide to Advanced Manufacturing

Insert molding isn’t just a buzzword in the manufacturing world — it’s a game-changer. If you’ve ever wondered how your phone charger stays so durable, or why that medical device holds together so seamlessly, chances are, insert molding is behind it. Let’s break down what it is, why it matters, and how it’s shaping modern product design.

What is Insert Molding?

Insert molding is a process where a pre-formed insert — usually metal or another rigid material — is placed into a mold, and molten plastic is injected around it. Once the plastic cools, you get a single, solid piece with the insert embedded inside.

Brief History and Evolution

Born from the evolution of traditional injection molding, insert molding became popular in the mid-20th century. As industries looked for ways to make products smaller, lighter, and stronger, combining materials in a single shot became the next big thing.

How Insert Molding Works

Basic Process Overview

Preparation of Inserts: Inserts (like screws, bushings, or even electrical connectors) are cleaned and sometimes coated to ensure proper bonding.

Mold Setup: Inserts are placed manually or automatically into the mold cavity.

Injection: Molten plastic is injected, encapsulating the insert and bonding with it as it cools.

Common Materials Used

Thermoplastics: ABS, Nylon, Polycarbonate

Insert Materials: Stainless steel, brass, ceramic, aluminum

Types of Inserts Used

Threaded Inserts

Ideal for assemblies that require frequent screwing and unscrewing.

Bushings and Bearings

Common in rotating components or mechanical joints.

Electronic Components

Used for embedding sensors, wires, or conductive paths into housings.

Custom-Designed Inserts

Tailored to specific product needs — think RFID chips or magnets.

Benefits of Insert Molding

Enhanced Durability

Parts are stronger because there are no weak bonding points or adhesives.

Cost-Efficiency

Combining assembly steps reduces labor and saves time.

Improved Product Aesthetics

No visible fasteners or glued joints. Just smooth, sleek finishes.

Space-Saving Designs

Perfect for compact electronics and wearable tech.

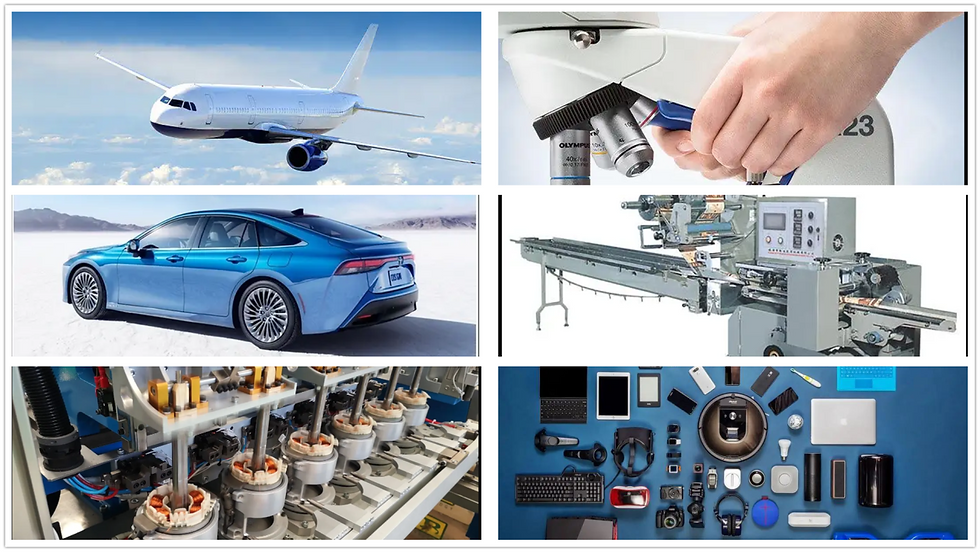

Applications of Insert Molding

Automotive Industry

Dashboard controls, sensor housings, gear knobs — all benefit from durable insert-molded parts.

Medical Devices

Safe, sterilizable, and precise components like syringe barrels or catheters.

Consumer Electronics

Think earbuds, charging cables, USB connectors — insert molding gives them strength without bulk.

Aerospace Components

Weight reduction and durability are critical here. Insert molding delivers both.

Comparison with Overmolding

Key Differences

Insert molding uses a pre-made insert.

Overmolding builds one layer of plastic over another.

When to Use Which?

Design Considerations

Mold Design Tips

Design around the insert’s shape and thermal conductivity.

Add features like undercuts or knurls for better bonding.

Insert Placement Guidelines

Keep inserts stable during injection — misalignment = defective part.

Material Compatibility

Not all metals bond well with all plastics. Match carefully.

Challenges and Solutions

Insert Misalignment

Solution: Use robotic insert placement or precision jigs.

Thermal Expansion Issues

Solution: Match insert and plastic expansion rates or leave room for movement.

Flashing and Warping

Solution: Perfect mold fit and process temperature control.

Quality Control and Testing

Inspection Techniques

Visual and dimensional checks

X-rays for hidden defects

Strength Testing

Pull tests to ensure the insert stays embedded

Electrical Continuity Testing

For molded-in electronic components

Equipment and Tooling

Specialized Molds

Precision molds built for the exact insert geometry

Injection Machines

Most standard injection machines can do insert molding with slight mods

Automation Options

Robotic arms for inserting — reduces labor and increases accuracy

Cost Factors

Tooling Costs

Higher initially due to complex molds

Material and Labor

Costs vary based on insert complexity and automation level

Volume Considerations

High-volume runs greatly reduce per-part cost

Trends in Insert Molding

Miniaturization

Smaller parts with even tinier inserts are the new normal

Eco-Friendly Materials

Bioplastics and recycled inserts are gaining ground

Smart Manufacturing

AI-driven molding machines and real-time quality monitoring

Selecting the Right Manufacturing Partner

What to Look For

Experience in insert molding

Cleanroom facilities (for medical or electronic parts)

Questions to Ask

Can you automate insert placement?

What’s your defect rate?

Certifications and Standards

ISO 9001, ISO 13485, and industry-specific certifications

Conclusion

Insert molding is a powerful meth

d that combines the strength of metals and the versatility of plastics in one seamless process. Whether you're building next-gen medical devices or rugged automotive components, it brings durability, precision, and efficiency. And with the rise of automation and sustainability, insert molding is not just the present — it’s the future.

FAQs

1. What materials are commonly used for inserts?Metals like brass, steel, and aluminum are most common, but ceramics and even some plastics are also used.

2. How strong is insert molding compared to traditional bonding? Much stronger! Since the plastic forms around the insert, the bond is mechanical and chemical.

3. Can you use multiple inserts in one part? Absolutely. Many complex components involve several inserts placed strategically.

4. Is insert molding suitable for small batch production? Yes, but setup costs may be higher. It’s best for medium to large volumes.

5. How does insert molding impact recycling? It complicates recycling because metal and plastic are fused. However, disassembly methods are evolving.

Comments