Laser Tube Cutting: The Ultimate Guide to Precision Tubular Fabrication

- shiva ganesh

- Jul 25

- 4 min read

Table of Content

Introduction to Laser Tube Cutting

What is Laser Tube Cutting?

Laser Tube Cutting is a specialized laser cutting process designed specifically for tubes, pipes, and profiles made from metals like steel, stainless steel, and aluminum. This method uses high-powered lasers (usually fiber lasers) combined with rotating and linear CNC-controlled movements to cut complex shapes, holes, slots, and profiles along the tube’s length and circumference.

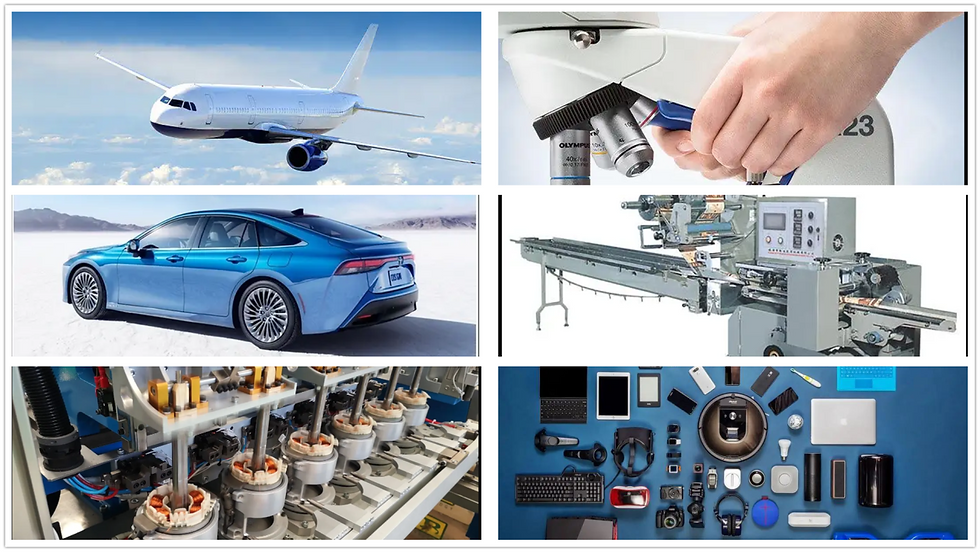

Laser tube cutting is widely used in automotive, aerospace, architecture, furniture, medical devices, and construction industries for precision, speed, and repeatability in producing structural or decorative tube components.

A Brief History of Laser Tube Cutting

The technology evolved from sheet metal laser cutting in the 1980s and became mainstream by the 1990s, thanks to advancements in rotational CNC axis control and fiber laser power. Today, laser tube cutting offers unmatched efficiency and accuracy for modern fabrication.

How Laser Tube Cutting Works

The Basic Workflow

Design the part using CAD software (specific to tubular geometries).

Generate the cutting path using CAM software, considering the tube's rotation and position.

Load the tube into the machine’s chuck and supports.

Clamp and rotate the tube precisely as the laser follows the programmed path.

Execute cuts for holes, slots, miters, and contours.

Inspect for dimensional accuracy and surface quality.

Key Components of a Laser Tube Cutting Machine

Fiber Laser Source

Generates the high-energy beam to cut through metals.

Cutting Head

Focuses the laser for precise cuts; often equipped with auto-focus features.

Tube Chuck System

Rotates and clamps the tube securely during cutting.

Support Systems

Maintain alignment and prevent sagging of long tubes.

CNC Controller

Coordinates all linear and rotational axes for complex geometries.

Laser Tube Cutting Processes

Straight Cuts

Clean, perpendicular cuts at specified lengths.

Angle/Mitre Cuts

Accurate angular cuts for welding or assembly.

Slots and Holes

Intricate shapes for mechanical or aesthetic purposes.

Contour Profiling

Complex patterns around the tube’s surface.

Perforation Patterns

Series of holes for lightweight structures or ventilation.

Materials Used in Laser Tube Cutting

Common Materials

Metals

Mild Steel

Stainless Steel

Aluminum

Brass

Copper

Titanium

Profile Shapes

Round Tubes

Square Tubes

Rectangular Tubes

Oval Tubes

Custom Profiles (L, U, H shapes)

Applications of Laser Tube Cutting

Automotive

Chassis structures, roll cages, exhaust systems, seat frames.

Aerospace

Lightweight structural elements, engine components.

Furniture

Modern steel or aluminum designs requiring precision joints.

Construction

Architectural frameworks, railings, curtain wall structures.

Medical Devices

Frames, supports, and ergonomic components.

Sports Equipment

Bicycle frames, gym equipment.

Advantages of Laser Tube Cutting

Precision and Clean Cuts

Tight tolerances with clean, burr-free edges.

Flexibility for Complex Designs

Can create slots, holes, contours, and miters in one setup.

Reduced Secondary Processing

Minimal need for deburring or finishing.

Faster Production

Automated systems increase throughput compared to manual methods.

Cost Efficiency

Reduces assembly time, welding, and fixtures thanks to precise cuts and fitments.

Limitations of Laser Tube Cutting

Material Thickness

Effective typically up to 10mm wall thickness depending on material and laser power.

Machine Investment

Higher upfront costs for specialized tube laser machines.

Reflective Materials

Challenges with highly reflective metals like brass or copper, requiring specialized fiber lasers.

Cutting Speed on Thick Tubes

Slower on thick-walled materials.

Laser Tube Cutting vs. Traditional Tube Cutting Methods

Key Differences

Feature | Laser Tube Cutting | Saw Cutting | Plasma Cutting | Manual Methods |

Precision | Very High (±0.1mm) | Moderate | Lower | Lower |

Edge Quality | Excellent | Requires finishing | Poor | Poor |

Geometry | Complex 3D profiles | Straight cuts only | Basic cuts | Basic cuts |

Speed | Fast (automated) | Moderate | Fast | Slow |

Cost | Higher initial | Lower initial | Moderate | Low |

When to Choose Laser Tube Cutting

For precision-fit components with complex profiles.

When accuracy, repeatability, and automation are priorities.

Ideal for prototyping through mass production.

Future Trends in Laser Tube Cutting

Integration with Automation

Automated loading, unloading, and sorting systems.

Higher-Power Fiber Lasers

Faster cutting of thicker walls and harder metals.

Smart Software

AI-driven nesting and cutting optimization to minimize waste.

Hybrid Machines

Combining tube cutting, bending, and welding in one setup.

Cost Considerations

Machine Cost

Entry-level: ₹1 crore – ₹2 crores

Industrial advanced: ₹2 crores – ₹5 crores+

Operational Costs

Energy for lasers and auxiliary equipment.

Assist gases (oxygen, nitrogen, air).

Maintenance of optics and chucks.

Part Cost

Lower in high-volume runs due to automation and speed.

Choosing the Right Laser Tube Cutting System

Based on Material

Ensure laser power matches material type and thickness (e.g., fiber lasers for metals).

Based on Application

Consider chuck size, rotation capabilities, and software flexibility for complex designs.

Volume Consideration

Best suited for medium to high production volumes with consistent tube profiles.

Tips for Getting Started with Laser Tube Cutting

Design for Laser Cutting

Incorporate tab and slot joints, self-locating features to ease assembly.

Select the Right Machine

Match machine specs to tube size range and complexity.

Optimize Material Usage

Efficient nesting reduces scrap and costs.

Invest in Training

Skilled operators maximize machine efficiency and quality output.

Conclusion

Laser Tube Cutting revolutionizes tubular fabrication, offering unmatched precision, flexibility, and efficiency. Whether for intricate architectural designs, lightweight aerospace structures, or robust automotive components, this technology enables faster production, lower costs, and superior quality.

Comments