Metal 3D Printing: The Ultimate Guide to Industrial Additive Manufacturing

- shiva ganesh

- Jul 30

- 4 min read

Table of content

Introduction to Metal 3D Printing

What is Metal 3D Printing?

Metal 3D Printing, also known as Metal Additive Manufacturing (Metal AM), is a cutting-edge technology that uses layer-by-layer techniques to fabricate fully functional metal parts directly from digital CAD models. Unlike traditional manufacturing that often removes material (subtractive), Metal 3D Printing builds complex geometries that would be impossible or highly inefficient to produce otherwise.

It is widely used in aerospace, automotive, medical, energy, and defense industries for producing lightweight, high-strength, and highly detailed parts.

A Brief History of Metal 3D Printing

The roots of Metal AM trace back to the 1990s, with technologies like Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) becoming commercially available in the 2000s. Over time, advances in laser precision, powder metallurgy, and process control have made Metal 3D Printing a reliable solution for production-level applications.

How Metal 3D Printing Works

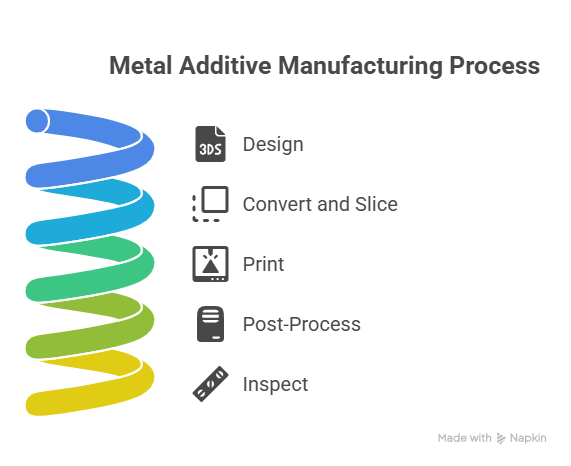

The Basic Workflow

Design the part in CAD software optimized for Metal AM (including support structures).

Convert and slice the file into layers via dedicated software.

Print using Metal 3D Printing technology (laser or binder jetting-based).

Post-process through heat treatment, support removal, and surface finishing.

Inspect via dimensional checks, CT scans, and mechanical testing.

Key Components of Metal 3D Printers

Laser / Electron Beam System

Provides the energy to fuse or melt the metal powder.

Powder Recoating System

Spreads thin, uniform layers of metal powder for each build layer.

Build Platform

Supports the part during layer-by-layer fabrication.

Inert Atmosphere Control

Maintains an oxygen-free environment to prevent oxidation.

Types of Metal 3D Printing Technologies

Powder Bed Fusion (PBF)

Direct Metal Laser Sintering (DMLS)

Selective Laser Melting (SLM)

Electron Beam Melting (EBM)

Binder Jetting (Metal)

Uses a binder to "glue" powder, followed by sintering.

Directed Energy Deposition (DED)

Laser or electron beam melts metal powder or wire fed simultaneously.

Metal Extrusion / Bound Metal Deposition (BMD)

Similar to FDM but uses metal-filled filaments and post-sintering.

Metal 3D Printing Process Examples

DMLS / SLM

Laser selectively melts powder layer-by-layer in a controlled environment.

EBM

Uses an electron beam in a vacuum to melt metal powder, ideal for titanium and aerospace alloys.

Binder Jetting

Applies a liquid binder to metal powder, later sintered into a dense part.

DED

Focuses energy to melt powder or wire as it's deposited onto a substrate.

Materials Used in Metal 3D Printing

Common Metal Alloys

Stainless Steels (316L, 17-4PH)

Corrosion resistance, strength for medical, automotive.

Titanium (Ti64)

Lightweight, strong, biocompatible for aerospace and medical.

Aluminum (AlSi10Mg)

Lightweight with good mechanical properties for automotive and aerospace.

Inconel (625, 718)

Nickel-based superalloys for extreme temperatures (aerospace, energy).

Cobalt-Chrome

High strength and wear resistance for dental and aerospace.

Tool Steels (H13, Maraging Steel)

Durability for tooling, molds, and dies.

Copper and Copper Alloys

Thermal and electrical applications.

Applications of Metal 3D Printing

Aerospace & Defense

Lightweight structures, complex ducts, brackets, and rocket components.

Automotive

Lightweight parts, heat exchangers, prototypes, motorsports components.

Medical

Orthopedic implants, surgical tools, dental implants.

Energy & Power

Turbine components, heat exchangers, manifolds.

Tooling & Manufacturing

Conformal cooling channels in molds, jigs, fixtures.

Advantages of Metal 3D Printing

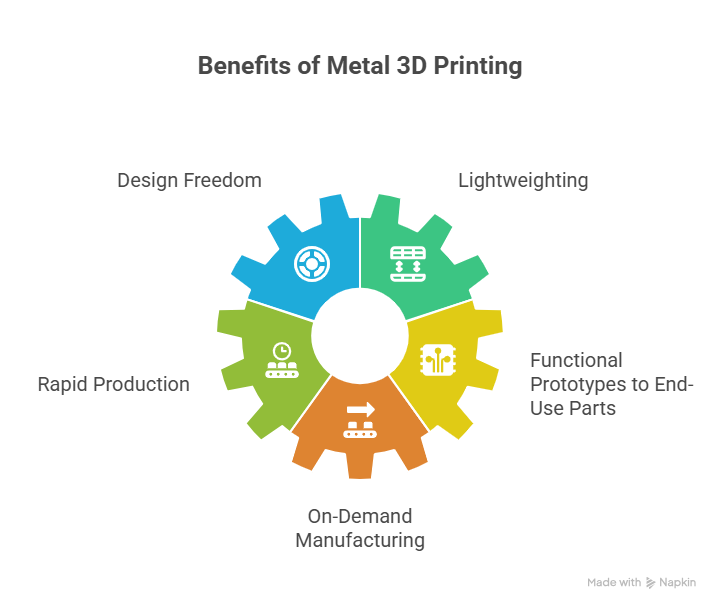

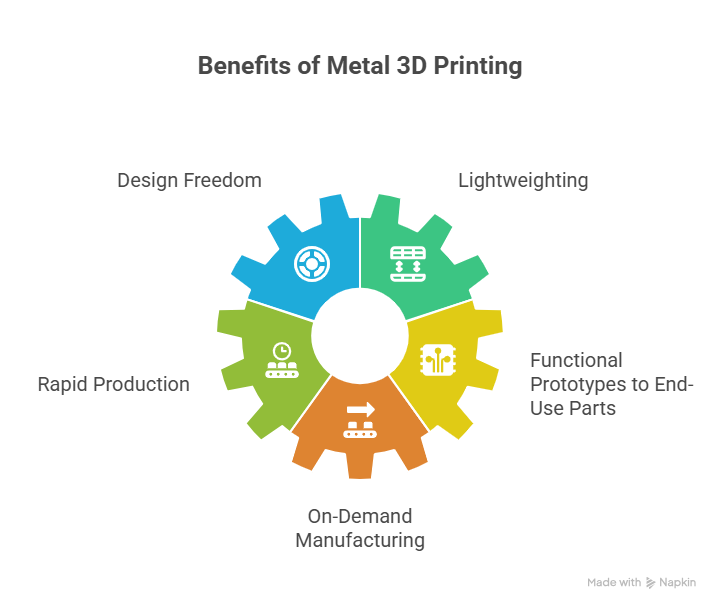

Design Freedom

Produce complex geometries, internal channels, and lattice structures impossible with traditional methods.

Lightweighting

Topology optimization reduces material usage without sacrificing strength.

Rapid Production

Eliminates tooling lead time for small to medium batches.

Functional Prototypes to End-Use Parts

Ideal for both prototyping and low-volume production.

On-Demand Manufacturing

Reduces inventory needs by printing parts as required.

Limitations of Metal 3D Printing

High Initial Costs

Machines, materials, and post-processing equipment are expensive.

Surface Roughness

Often requires post-processing for critical surfaces.

Build Size Limitations

Build volumes are smaller compared to casting or machining.

Support Structures Needed

Metal parts typically require supports to manage heat and distortion.

Metal 3D Printing vs. Traditional Metal Manufacturing

Key Differences

Feature | Metal 3D Printing | Traditional (Casting / Machining) |

Setup Cost | Low for low volume | High (tooling, molds, dies) |

Production Speed | Fast for complex parts | Slow setup, fast once scaled |

Design Flexibility | Very High | Limited |

Unit Cost | High (low volume) | Low (high volume) |

Geometries | Complex, internal | Limited without secondary machining |

When to Choose Metal 3D Printing

For complex, low-volume, high-performance parts.

For prototyping functional metal components.

When lightweighting or consolidation is required.

Future Trends in Metal 3D Printing

Material Advancements

More alloy options, higher performance metals.

Increased Production Adoption

From prototyping to regular production in aerospace, medical, automotive.

Process Automation

Streamlined post-processing, powder handling, and inspection.

Hybrid Manufacturing

Combination with subtractive methods for high precision and speed.

Cost Considerations

Cost of Machines

Ranges from ₹50 lakhs to ₹5 crores based on technology and build volume.

Operational Costs

Powder materials are expensive (₹20,000+ per kg).

Post-processing costs for heat treatment, machining, polishing.

Typical Price Range

Small parts: ₹2,000 to ₹50,000+ per unit.

Large, complex parts: Significantly higher.

Choosing the Right Metal 3D Printing Technology

Based on Material and Application

DMLS/SLM: Aerospace, medical, tooling, complex parts.

EBM: High-temp aerospace parts (titanium).

Binder Jetting: Cost-effective for batch production.

DED: Repairs, large parts, aerospace structures.

Based on Production Volume

Prototypes / Small Batches: DMLS, SLM, EBM.

Larger Volumes: Binder Jetting, Hybrid AM.

Tips for Getting Started with Metal 3D Printing

Design for Additive Manufacturing (DfAM)

Leverage lightweighting, lattice structures, and heat management.

Understand Post-Processing Needs

Plan for heat treatment, machining, and surface finishing from the start.

Select Certified Providers

For critical applications, ensure ISO 9001, AS9100, or medical certifications.

Start with Prototypes, Scale Gradually

Validate designs before committing to production runs.

Conclusion

Metal 3D Printing is transforming manufacturing by enabling complex, lightweight, and high-performance parts across industries. With advances in materials, processes, and scalability, it’s no longer just a prototyping tool—it’s a viable solution for production and end-use manufacturing.

Comments