Metal Binder Jetting: The Ultimate Guide to Metal 3D Printing for Mass Production

- shiva ganesh

- Jul 30

- 4 min read

Table of Content

Introduction to Metal Binder Jetting

What is Metal Binder Jetting?

Metal Binder Jetting (MBJ) is an additive manufacturing process that prints metal parts by selectively depositing a liquid binder onto layers of metal powder. After printing, the "green" parts are sintered in a furnace, where the binder burns away and the meta

Metal Binder Jetting vs. Other Metal 3D Printing Technologies

Key Differencesl particles fuse to form a solid, dense structure.

Unlike laser-based metal 3D printing, Binder Jetting doesn't use heat during printing, making it faster, more scalable, and more cost-effective for high-volume production of metal parts.

A Brief History of Metal Binder Jetting

Binder Jetting technology was first introduced in the 1990s at MIT. Over time, companies like ExOne (now part of Desktop Metal), HP, and GE Additive have advanced MBJ to a reliable production-level solution. Today, it's gaining widespread adoption for producing complex, lightweight, and cost-efficient metal components at industrial scales.

Cost Considerations

How Metal Binder Jetting Works

The Basic Workflow

Design the part in CAD software.

Slice the model into layers via Binder Jetting software.

Print: A printhead selectively deposits binder onto a metal powder bed, layer by layer.

Depowder: Remove excess powder after printing.

Cure: Harden the green part with heat or chemicals.

Sinter: Furnace processing burns away the binder and densifies the metal.

Optional Post-Processing: Infiltration, machining, or surface finishing.

Key Components of Metal

Binder Jetting Printers

Printhead

Applies a liquid binder selectively to fuse powder particles temporarily.

Powder Bed

A fine layer of metal powder is spread for each layer.

Recoater

Distributes thin, uniform powder layers across the build area.

Build Platform

Supports multiple parts simultaneously in a single batch.

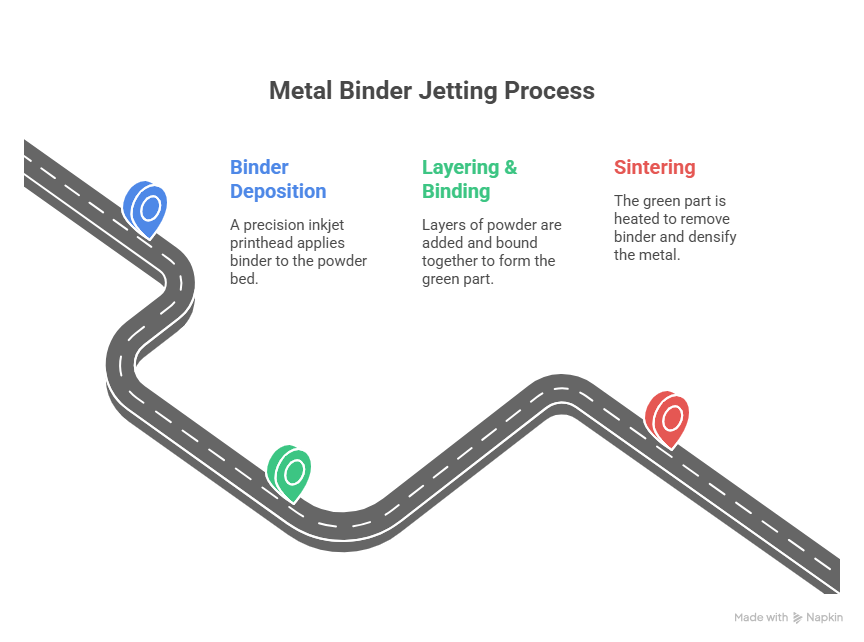

Metal Binder Jetting Process

Binder Deposition

A precision inkjet printhead applies the binder only where the part geometry exists.

Layering & Binding

The process repeats layer-by-layer until the full "green part" is for

Tips for Getting Started with Metal Binder med within a box of loose powder.

Sintering

Post-print, the green parts are heated in a furnace to eliminate the binder and densify

Choosing the Right Metal Binder Jetting Setupthe structure to near-solid metal.

Materials Used in Metal Binder Jetting

Common Metal Alloys

Stainless Steels (316L, 17-4PH)

Corrosion resistance, strength for tooling, medical, and consumer goods.

Inconel (625, 718)

Nickel-based alloys for high-temperature, corrosive environments.

Copper

Excellent electrical and thermal conductivity applications.

Tool Steels (H13, M2)

For high-wear industrial tools, dies, and molds.

Titanium (under development)

Emerging but less common than in DMLS or EBM.

Aluminum (limited availability)

Still maturing due to sintering challenges.

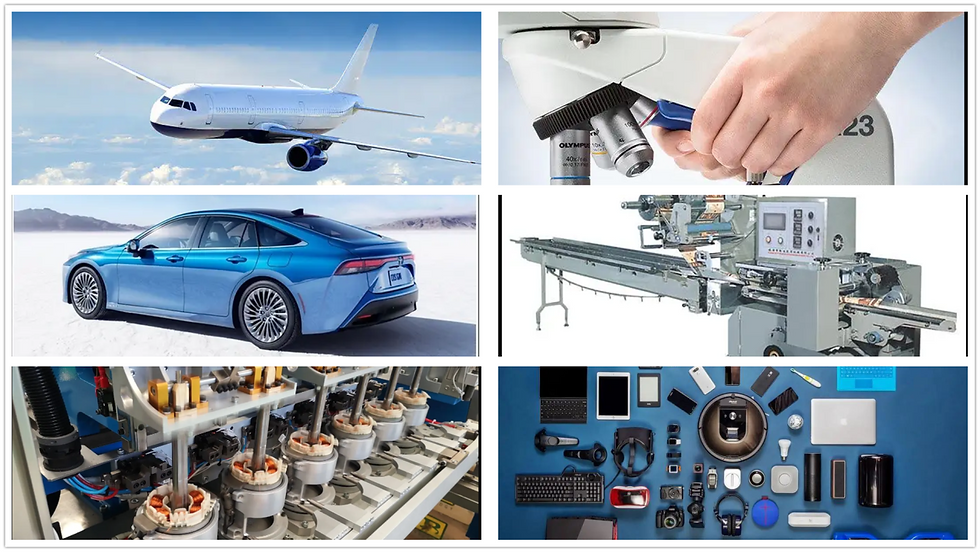

Applications of Metal Binder Jetting

Automotive

Brackets, housings, gears, and structural components for light weighting and performance.

Consumer Goods

Custom jewelry, hardware, kitchen tools, and wearables.

Medical

Surgical instruments, orthopedic devices (limited use compared to DMLS).

Industrial Tooling

Dies, molds, cutting tools, fixtures.

Energy & Electronics

Heat sinks, conductive parts, complex geometries.

Advantages of Metal Binder Jetting

Scalability

Multiple parts in a single build; ideal for batch production.

Cost-Effective

Lower part cost for volume production compared to laser-based methods.

High Throughput

Large build volumes and fast print speeds.

Complex Geometries

Internal channels, lattice structures, and consolidated assemblies.

No Supports During Printing

Parts are supported by surrounding loose powder, simplifying design.

Limitations of Metal Binder Jetting

Requires Sintering

Significant shrinkage and deformation risk during furnace processing.

Material Density

Typically achieves 95-99% density, slightly less than DMLS or forged parts.

Surface Finish

Surface roughness is moderate and often requires finishing.

Limited High-Performance Alloys

Not all metals sinter well; options are more limited than laser systems.

Post-Processing Complexity

Debinding, sintering, infiltration, or machining are necessary steps.

Metal Binder Jetting vs. Other Metal 3D Printing Technologies

Key Differences

Feature | Binder Jetting | DMLS / SLM | EBM | DED |

Energy Source | Liquid binder + furnace | Laser | Electron Beam | Laser / Electron |

Supports | No supports needed | Required | Required | None / Minimal |

Build Speed | Fast | Moderate | Moderate | Slow |

Best Use | High-volume production | High-performance parts | Aerospace parts | Repairs, Large |

Surface Finish | Moderate (post-process) | Fine (post-process) | Rough | Rough |

When to Choose Metal Binder Jetting

For large batch production of small to medium parts.

When cost-efficiency outweighs maximum strength.

For complex parts not requiring ultra-high precision.

Future Trends in Metal Binder Jetting

Material Expansion

Improved sintering methods for aluminum, titanium, and more complex alloys.

Automation & Scalability

Streamlined depowdering, sintering, and finishing for higher throughput.

Hybrid Manufacturing

Binder Jetting for complex geometries combined with machining for precision.

Industry Adoption

Automotive and consumer sectors driving mass production adoption.

Cost Considerations

Machine Cost

Ranges from ₹70 lakhs to ₹3 crores, depending on build volume and speed.

Operational Costs

Metal powder is cheaper than laser-grade powders.

Post-processing adds costs for sintering, infiltration, finishing.

Part Cost

Lower than DMLS for batch production.

Parts typically ₹500 to ₹10,000+ depending on complexity and size.

Choosing the Right Metal Binder Jetting Setup

Based on Material

Stainless Steel, Inconel, Copper: Most common and mature.

Aluminum, Titanium: Emerging, still limited.

Based on Production Volume

Mid-to-high batch production: Binder Jetting is ideal.

Prototypes or single parts: DMLS / SLM may offer more control.

Tips for Getting Started with Metal Binder

Jetting

Design for Sintering

Account for shrinkage, powder removal, and warpage during furnace processing.

Plan Post-Processing

Ensure you understand the need for machining, infiltration, polishing.

Evaluate for Scale

Binder Jetting shines in batch runs, not small prototype series.

Work with Experts

Partner with experienced service bureaus or OEM-certified providers.

Conclusion

Metal Binder Jetting is redefining scalable metal 3D printing by offering cost-effective, high-volume, complex part production. While it requires careful post-processing, it provides unmatched value for industries seeking rapid, affordable metal manufacturing at scale.

Comments