Plastic 3D Printing: The Ultimate Guide to Additive Manufacturing with Polymers

- shiva ganesh

- Jul 30

- 4 min read

Table of Content

Introduction to Plastic 3D Printing

What is Plastic 3D Printing?

Plastic 3D printing is a type of additive manufacturing that specifically utilizes thermoplastic materials to create parts layer-by-layer from a digital model. It is one of the most accessible and widely used forms of 3D printing, known for rapid prototyping, complex geometries, and cost-effective low-volume production.

A Brief History of Plastic 3D Printing

Plastic 3D printing began with stereolithography (SLA) in the 1980s. The 1990s brought Fused Deposition Modeling (FDM), which revolutionized accessibility to 3D printing, particularly for plastics. Over time, material quality and machine precision have evolved, making plastic 3D printing essential for industries from automotive to healthcare.

How Plastic 3D Printing Works

The Basic Workflow

Plastic 3D printing involves the following steps:

Design the model in CAD software.

Slice the model into layers via slicing ``software.

Load the file into the 3D printer.

Print the object by heating and depositing a plastic layer by layer.

Post-process for support removal, surface finish, or painting.

Key Components of Plastic 3D Printers

Extruder / Nozzle (FDM)

Heats and extrudes thermoplastic filament through a small nozzle.

Resin Vat / Light Source (SLA/DLP)

Solidifies liquid resin using UV light layer-by-layer.

Build Platform / Bed

Supports the object as it is printed from the bottom up.

Controller

Operates the printer, following the slicing instructions.

Types of Plastic 3D Printers

FDM (Fused Deposition Modeling)

Heats thermoplastic filament and extrudes it in layers. Most common for general-purpose plastic parts.

SLA (Stereolithography)

Uses UV light to cure liquid resin. Ideal for highly detailed, smooth plastic components.

SLS (Selective Laser Sintering)

Fuses powdered thermoplastics with a laser. Suitable for functional prototypes and complex geometries.

PolyJet / Multi-Jet Fusion

Sprays resin droplets cured by light. Allows multi-material and high-detail printing.

Plastic 3D Printing Processes

Extrusion-Based (FDM)

Thermoplastic filament is melted and extruded layer by layer.

Vat Photopolymerization (SLA/DLP)

Liquid resin is solidified by light.

Powder Bed Fusion (SLS)

Thermoplastic powder is selectively fused using heat.

Material Jetting

Sprays and cures photopolymers for detailed parts.

Materials Used in Plastic 3D Printing

Thermoplastics

PLA (Polylactic Acid)

Easy to print, biodegradable, ideal for general prototypes.

ABS (Acrylonitrile Butadiene Styrene)

Tough, heat-resistant, used in automotive and functional parts.

PETG (Polyethylene Terephthalate Glycol)

Strong, chemically resistant, food-safe.

Nylon (Polyamide)

Durable, flexible, used for gears, hinges, and wear-resistant parts.

TPU (Thermoplastic Polyurethane)

Flexible, rubber-like, used for seals, insoles, and soft-touch parts.

Photopolymers (Resins)

Used in SLA/DLP for high detail and smooth finishes; available in standard, tough, flexible, and dental variants.

Applications of Plastic 3D Printing

Prototyping

Quick iterations of design concepts for review and testing.

Consumer Products

Cases, enclosures, home appliances, and accessories.

Medical

Surgical models, dental appliances, and prosthetic components.

Education

Visual aids, teaching tools, and project prototypes.

Architecture

Scaled models, intricate design elements.

Advantages of Plastic 3D Printing

Cost-Effective Prototyping

Affordable materials and machines for quick design iterations.

Design Flexibility

Complex geometries and organic shapes are easily achievable.

Lightweight Components

Plastic parts are ideal where weight reduction matters.

Material Variety

Wide range of plastics for varied applications.

Limitations of Plastic 3D Printing

Mechanical Strength

Weaker than metals; some plastics may not endure high-stress environments.

Heat Resistance

Most thermoplastics deform at lower temperatures compared to metals.

Surface Finish

May require post-processing for a smooth or aesthetic finish.

Dimensional Accuracy

Warpage and shrinkage can affect precision without proper calibration.

Plastic 3D Printing vs. CNC Machining

Key Differences

Feature | Plastic 3D Printing | CNC Machining |

Process | Additive | Subtractive |

Material | Thermoplastics, Resins | Metals, Plastics |

Cost | Lower for low volume | Higher setup cost |

Speed | Faster for prototypes | Faster for mass production |

Detail | Complex geometries | High-precision parts |

When to Choose One Over the Other

Plastic 3D Printing: Ideal for prototypes, complex shapes, and small runs.

CNC Machining: Ideal for precision, durability, and high-stress applications.

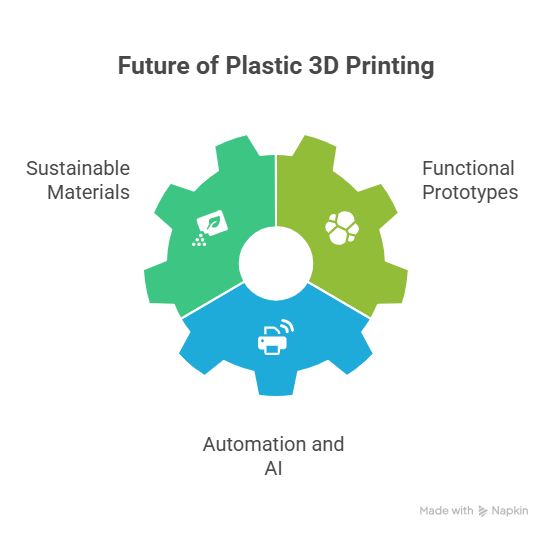

Future Trends in Plastic 3D Printing

Sustainable Materials

Development of biodegradable and recyclable plastics.

Functional Prototypes

Increased use of high-performance plastics for end-use parts.

Automation and AI

Smarter printers, AI-driven slicing, and fully automated print farms.

Cost Considerations

Cost of Machines

₹30,000 to ₹3 lakhs for FDM; ₹2 lakhs to ₹10 lakhs+ for industrial SLA or SLS systems.

Cost of Operation and Maintenance

Includes filaments/resins, regular maintenance, calibration, and software.

Choosing the Right Plastic 3D Printer

Based on Material and Application

FDM: General purpose

SLA: High detail, aesthetics

SLS: Functional prototypes, complex geometries

Based on Production Volume

Hobby / Prototype: Desktop FDM

Small Batch / Functional: SLS / Industrial FDM / SLA

Tips for Getting Started with Plastic 3D Printing

Training and Certifications

Online courses: Coursera, Udemy, LinkedIn Learning

Manufacturer certifications: Formlabs, Ultimaker

Recommended Tools and Resources

YouTube: Maker’s Muse, 3D Printing Nerd

Communities: r/3Dprinting, Prusa forums

Books: "The 3D Printing Handbook" by 3D Hubs

Conclusion

Plastic 3D printing democratizes manufacturing, making prototyping and small-scale production affordable and efficient. From educational models to production aids, it brings ideas to life with speed, flexibility, and creativity.

Comments