Plastic Injection Molding: The Ultimate Guide to High-Volume Manufacturing

- shiva ganesh

- Jul 24

- 4 min read

Table Of Content

Introduction to Plastic Injection Molding

What is Plastic Injection Molding?

Plastic Injection Molding is a highly efficient manufacturing process used to produce large volumes of identical plastic parts with excellent precision, consistency, and durability. It involves injecting molten thermoplastic material into a precisely machined mold, where it cools and solidifies into the desired shape.

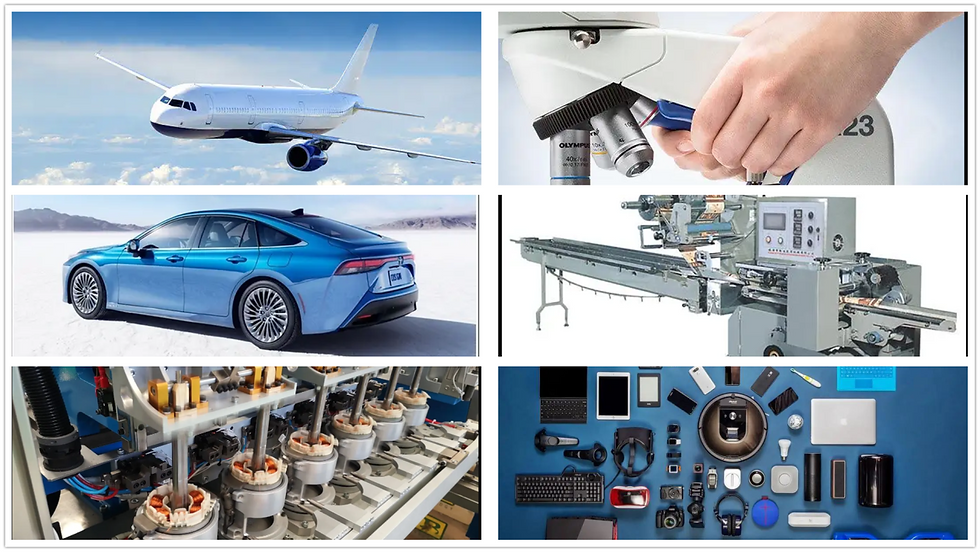

This process is widely utilized in industries like automotive, consumer electronics, medical devices, packaging, and appliances, where consistency, scale, and durability are crucial.

A Brief History of Plastic Injection Molding

Developed in the late 1800s, early injection molding machines focused on simple parts like buttons and combs. By the 1940s-50s, advancements in thermoplastics and automated tooling transformed it into a key technology for mass production. Today, it supports everything from precision medical components to complex automotive parts.

How Plastic Injection Molding Works

The Basic Workflow

Design the part using CAD software, considering moldability and shrinkage.

Create the mold, typically from hardened steel or aluminum.

Heat thermoplastic pellets to a molten state.

Inject the molten plastic into the mold cavity under high pressure.

Cool the material within the mold until it solidifies.

Eject the completed part for post-processing if necessary.

Key Components of an Injection Molding Machine

Injection Unit

Melts and injects the plastic material.

Clamping Unit

Holds the mold tightly during injection and cooling.

Mold

Custom-fabricated tooling defining the final shape of the part.

Cooling System

Circulates water or oil to regulate mold temperature.

Ejection System

Releases the part from the mold cavity once cooled.

Types of Plastic Injection Molding

Standard Injection Molding

For high-volume production of simple or complex parts.

Insert Molding

Integrates metal or plastic inserts within molded parts.

Overmolding

Molds soft materials over hard substrates for improved grip or aesthetics.

Gas-Assisted Injection Molding

Uses gas to create hollow sections, reducing weight and material use.

Micro Injection Molding

For extremely small, precise components like medical devices.

Materials Used in Plastic Injection Molding

Common Thermoplastics

Commodity Plastics

Polypropylene (PP)

Polyethylene (PE)

Polystyrene (PS)

PVC

Engineering Plastics

ABS

Nylon (PA)

Polycarbonate (PC)

POM (Acetal)

High-Performance Plastics

PEEK

Ultem (PEI)

PTFE

Applications of Plastic Injection Molding

Automotive

Dashboards, trims, housings, fasteners, fluid system components.

Medical Devices

Syringes, diagnostic devices, surgical instruments, housings.

Consumer Electronics

Phone cases, connectors, structural frames, enclosures.

Packaging

Caps, closures, containers, dispensers.

Appliances

Knobs, panels, components for washers, dryers, refrigerators.

Advantages of Plastic Injection Molding

High Efficiency

Ideal for high-volume production with fast cycle times.

Consistency and Precision

Produces identical parts with tight tolerances.

Material Flexibility

Wide choice of plastics with various mechanical, thermal, and aesthetic properties.

Complex Geometries

Supports intricate designs, undercuts, and detailed textures.

Low Unit Cost

High initial tooling cost offset by economies of scale.

Limitations of Plastic Injection Molding

High Initial Tooling Cost

Expensive to create molds, especially for complex parts.

Design Constraints

Parts must be designed for mold ability (draft angles, uniform wall thickness).

Lead Time

Tooling fabrication can take 4–12 weeks before production.

Material Waste

Gate, runner, and sprue waste unless using hot-runner systems.

Plastic Injection Molding vs. 3D Printing vs. CNC Machining

Key Differences

Feature | Injection Molding | 3D Printing | CNC Machining |

Volume | High | Low to Medium | Low to Medium |

Speed per Part | Fast (seconds) | Slow (hours) | Moderate |

Precision | Very High (±0.1mm) | Good (±0.2mm) | High (±0.05mm) |

Setup Cost | High (molds) | Low | Moderate |

Part Cost | Very Low (volume) | Higher per part | Moderate |

Complexity | Complex shapes | Organic shapes | Machined forms |

When to Choose Plastic Injection Molding

For mass production where consistency and part quality matter.

When requiring robust mechanical properties.

Ideal for consumer, automotive, and medical products.

Future Trends in Plastic Injection Molding

Digital Manufacturing Integration

Smart machines with AI-driven process optimization.

Sustainable Materials

Growth of bio-based and recycled plastics in production.

Conformal Cooling

3D-printed mold inserts to improve cooling efficiency and cycle times.

Automation & Robotics

Increased use of robotic handling for lights-out manufacturing.

Cost Considerations

Tooling Cost

Prototype tools: ₹2 lakh – ₹10 lakh+

Production tools: ₹10 lakh – ₹50 lakh+

Production Cost

Economical per part at high volumes (tens of thousands to millions).

Operational Costs

Maintenance, materials, energy consumption.

Choosing the Right Plastic Injection Molding Partner

Based on Project Needs

Volume: Prototype vs. production.

Complexity: Simple shapes vs. high-detail parts.

Certifications

ISO 9001, IATF 16949 for automotive, ISO 13485 for medical.

Value-Added Services

DFM support

Mold maintenance

Secondary operations (painting, assembly)

Tips for Getting Started with Plastic Injection Molding

Design for Manufacturability (DFM)

Optimize designs for mold flow, ejection, and cooling.

Partner with Experts

Engage manufacturers early for advice on materials, tooling, and design.

Understand Lead Times

Account for tooling fabrication and sampling in your project timelines.

Consider Prototype Molds

Use soft tooling (aluminum) for small runs before full production.

Conclusion

Plastic Injection Molding remains the gold standard for producing precise, durable, and high-volume plastic components. Whether for everyday consumer goods or specialized medical devices, this process delivers unmatched efficiency, repeatability, and material performance at scale.

Comments