PolyJet 3D Printing: The Ultimate Guide to High-Resolution Multi-Material Printing

- shiva ganesh

- Jul 30

- 4 min read

Table of Contents

Introduction to PolyJet 3D Printing

What is PolyJet 3D Printing?

PolyJet is an advanced material jetting 3D printing technology developed by Stratasys. It operates by jetting layers of liquid photopolymer onto a build platform and curing them instantly with UV light. PolyJet is renowned for its high-resolution surface finish, precision, and multi-material capabilities, enabling prints with varying colors, transparencies, and material properties in a single build.

A Brief History of PolyJet Technology

Introduced by Objet Geometries (now Stratasys) in 2000, PolyJet revolutionized 3D printing by combining fine resolution, multiple materials, and color capabilities. It remains a go-to technology for industries needing highly detailed prototypes, including medical, automotive, and consumer products.

How PolyJet Works

The Basic Workflow

Design the part in CAD software.

Prepare and slice the model using PolyJet-compatible software.

Load the file into the PolyJet printer.

Print by jetting photopolymer droplets layer-by-layer and curing with UV light.

Post-process by removing support material (typically water-soluble or mechanically).

Key Components of PolyJet Printers

Print Head Arrays

Jet tiny droplets of photopolymer and support material simultaneously.

UV Curing Lamps

Instantly solidify the material as it is deposited.

Build Platform

Supports the printed object layer-by-layer during the build process.

Control System

Manages precise droplet deposition, layer thickness, and material blending.

Types of PolyJet Printers

Stratasys J-Series (J850, J826, etc.)

Industrial-grade for full-color, multi-material, and high-resolution prints.

Stratasys Objet Series (Objet30, Objet260, etc.)

Smaller footprint for detailed prototypes and functional models.

Connex Series

Known for multi-material capabilities and highly detailed models.

PolyJet Printing Process

Material Jetting with UV Curing

PolyJet jets thousands of microscopic droplets of liquid photopolymer onto the build platform. These droplets are immediately cured by UV light, solidifying them layer-by-layer to form the final object.

Supports: Gel-like, removable manually or via water jets.

Materials: Simultaneously combine rigid, flexible, transparent, and colored materials.

Materials Used in PolyJet 3D Printing

Photopolymer Resins

Rigid Opaque Resins

For functional prototypes with crisp detail.

Rubber-Like (Flexible) Resins

Simulate elastomers, ideal for grips, seals, and gaskets.

Transparent Resins

For lenses, light covers, and visual prototypes.

High-Temperature Resins

For parts needing heat resistance.

Biocompatible Resins

Medical devices, dental applications.

Digital Materials (Composite Blends)

Combine properties like rigid + flexible or transparent + colored in a single print.

Applications of PolyJet 3D Printing

Medical and Dental

Surgical guides, anatomical models, dental molds, and orthodontics.

Consumer Goods & Electronics

Prototypes for housings, buttons, consumer devices with color accuracy.

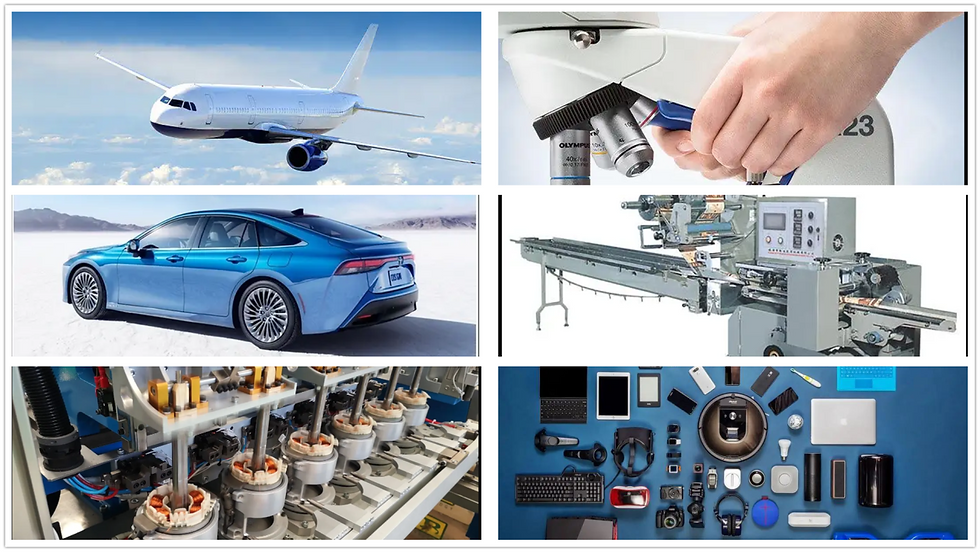

Automotive & Aerospace

Visual prototypes, interior components, ergonomic testing models.

Education & Research

Teaching aids, museum replicas, scientific visualization.

Jewelry & Fashion

Master patterns, intricate prototypes, and design validation.

Advantages of PolyJet 3D Printing

Ultra-High Resolution and Surface Finish

Achieves smooth surfaces and fine details down to 16 microns layer thickness.

Multi-Material & Color Capabilities

Combines rigid, flexible, transparent, and full-color materials in a single print.

Accurate and Detailed

Perfect for concept models, fit-check prototypes, and medical replicas.

Versatile

Simulate multiple material properties without multiple machines or assemblies.

Limitations of PolyJet 3D Printing

Material Fragility

Photopolymers lack the durability of thermoplastics and degrade over time.

Post-Processing Required

Supports require washing or manual removal; post-curing may be necessary.

UV Sensitivity

Printed parts can yellow or become brittle with prolonged UV exposure.

High Cost of Operation

Consumables and material costs are higher than FDM or SLA.

PolyJet vs. Other 3D Printing Technologies

Key Differences

Feature | PolyJet | SLA | FDM | SLS |

Process | Material jetting | Light-curing resin | Filament extrusion | Laser sintering powder |

Resolution | Ultra-fine (16µm) | Very fine | Moderate | High |

Surface Finish | Smoothest | Smooth | Layered texture | Powdery finish |

Supports | Required (Gel-like) | Required | Required | Not required |

Best Use | Prototypes, visuals | Prototypes, dental | Functional prototypes | Functional parts |

When to Choose PolyJet

For visual prototypes requiring color, transparency, or texture simulation.

For medical and anatomical models demanding accuracy.

For design validation, prototypes in consumer products.

Future Trends in PolyJet 3D Printing Limitations of PolyJet 3D Printing

Expanded Color and Material Libraries

Wider material options for simulating diverse real-world materials.

Increased Integration with AR/VR Design

Direct correlation between digital twins and printed models.

Advancements in Biocompatible Materials

Greater adoption in medical devices and surgical planning.

Cost Considerations

Cost of Machines

Ranges from ₹30 lakhs to ₹2 crores, depending on resolution, build volume, and materials supported.

Cost of Operation and Maintenance

Includes resins (expensive), cleaning agents, maintenance kits, and support removal systems.

Choosing the Right PolyJet Printer

Based on Material and Application

Multi-Material / Color: J-Series

Prototypes / Visual Models: Objet or Connex

Medical / Dental: Biocompatible-specific models

Based on Production Volume

Low-Volume, High-Detail: Objet, Connex

Advanced Prototyping Farms: J-Series, high-capacity units

Tips for Getting Started with PolyJet

Training and Certifications

Stratasys-certified training programs.

Courses on CAD for additive manufacturing and color modeling.

Recommended Tools and Resources

Communities: GrabCAD, Stratasys user groups

Events: Rapid+TCT, Formnext

Software: GrabCAD Print, PolyJet Studio, KeyShot for rendering

Conclusion

PolyJet 3D printing is the gold standard for high-fidelity, multi-material, and full-color prototypes. While it isn’t suited for heavy-duty functional parts, its precision and versatility make it a vital tool in product design, healthcare, and advanced prototyping.

FAQs

What materials are used in PolyJet 3D printing? Photopolymer resins including rigid, flexible, transparent, biocompatible, and high-temp.

Is PolyJet better than SLA?For multi-material, color, and flexibility simulations—yes. For simple, strong prototypes, SLA might suffice.

How expensive is a PolyJet printer? Ranges from ₹30 lakhs to ₹2 crores based on capability and build size.

What industries use PolyJet the most? Medical, dental, consumer goods, automotive, and aerospace.

Do PolyJet parts require post-processing? Yes. Support removal and cleaning are necessary, sometimes followed by light sanding or polishing.

Comments