Production 3D Printing: The Ultimate Guide to On-Demand Manufacturing

- shiva ganesh

- Jul 30

- 4 min read

Table of Content

Introduction to Production 3D Printing Services

What is a Production 3D Printing Service?

Production 3D Printing Services offer on-demand manufacturing solutions using various advanced 3D printing technologies to produce functional, end-use parts in small to medium volumes. Unlike prototyping services, these services focus on consistent quality, repeatability, scalability, and industrial-grade materials suitable for final products.

Production 3D Printing bridges the gap between prototype validation and full-scale manufacturing, making it ideal for industries seeking flexibility, speed, and cost efficiency without investing in expensive tooling.

A Brief History of 3D Printing for Production

Initially limited to prototyping, 3D printing evolved with advances in material properties, machine reliability, and automation. Technologies like SLS, MJF, and FDM have matured, allowing companies to confidently produce functional components for direct end-use in sectors like aerospace, automotive, medical, and consumer goods.

How Production 3D Printing Services Work

The Basic Workflow

Design finalized CAD files with manufacturing constraints considered.

Submit to a service provider through digital platforms.

DFM Review (Design for Manufacturability) and quotation by the provider.

Production using appropriate 3D printing technology (SLS, MJF, SLA, FDM, etc.).

Post-Processing including cleaning, finishing, dyeing, or coating.

Quality Inspection to verify dimensional accuracy and consistency.

Shipping the finished parts to the customer.

Key Components of a 3D Printing Service Workflow

Pre-Processing

File preparation, nesting, support generation, and material selection.

Printing Technologies Available

SLS, MJF, SLA, DMLS/SLM (metal), FDM, PolyJet, Carbon DLS, etc.

Post-Processing

Surface finishing, coloring, smoothing, heat treatments, machining.

Quality Assurance

Dimensional inspection, mechanical testing, material certification.

Types of 3D Printing Services for Production

Polymer-Based Services

Selective Laser Sintering (SLS)

Multi Jet Fusion (MJF)

Fused Deposition Modeling (FDM)

Stereolithography (SLA)

Carbon DLS / CLIP

PolyJet

Metal-Based Services

Direct Metal Laser Sintering (DMLS)

Selective Laser Melting (SLM)

Binder Jetting (Metal)

Electron Beam Melting (EBM)

Applications of Production 3D Printing Services

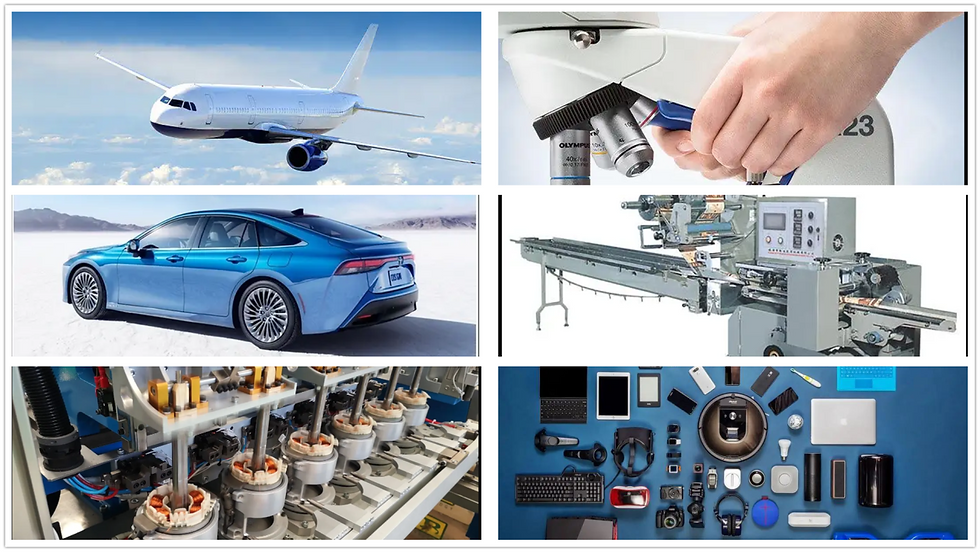

Aerospace & Defense

Lightweight components, ducting, brackets, UAV parts.

Automotive

Custom parts, tooling, fixtures, functional assemblies.

Medical & Dental

Implants, surgical guides, prosthetics, orthodontics.

Consumer Products

Wearables, eyewear, custom electronics housings.

Industrial Manufacturing

Jigs, fixtures, end-of-arm tooling, housings.

Robotics & Electronics

Functional enclosures, structural frames, mounts.

Advantages of Production 3D Printing Services

No Tooling Required

No upfront mold or die cost, making it ideal for low-to-medium batch production.

Rapid Turnaround

Lead times often reduced from months to days or weeks.

Design Flexibility

Complex geometries, lightweight structures, lattice designs easily achievable.

Customization at Scale

Mass customization is possible without increasing costs per unit.

On-Demand Inventory

Reduce storage by producing parts as needed.

Limitations of Production 3D Printing Services

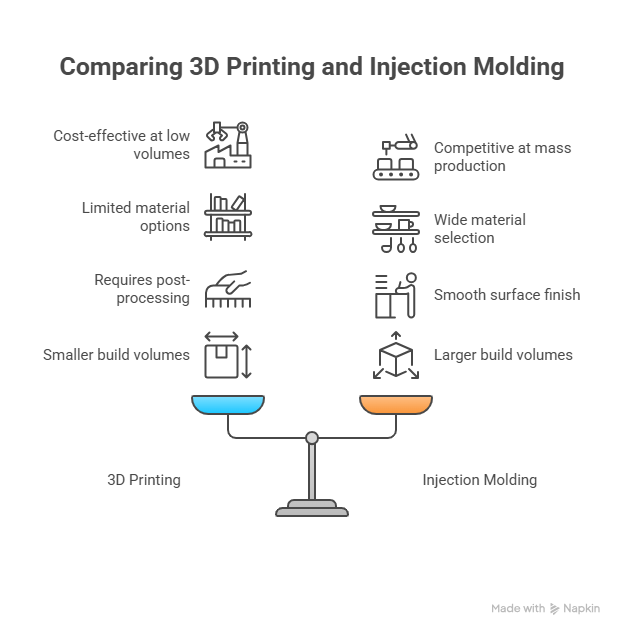

Unit Cost at Scale

More cost-effective at low-to-medium volumes, less competitive at mass production scales compared to injection molding.

Material Constraints

Limited to specific polymers and metals suitable for additive processes.

Surface Finish

Often requires post-processing to achieve aesthetic or functional finishes.

Size Constraints

Build volumes are smaller compared to traditional manufacturing methods.

Production 3D Printing vs. Traditional Manufacturing

Key Differences

Aspect | 3D Printing Production | Traditional Manufacturing |

Setup Cost | Low | High (tooling, molds) |

Lead Time | Fast | Slower (tooling + production) |

Flexibility | High | Low once tools are made |

Unit Cost | Flat (low volume) | Reduces with high volume |

Complexity | Free | Increases cost |

When to Choose 3D Printing Services

For low-volume production.

When complex geometries or lightweight designs are needed.

For functional testing, rapid iteration, and customization.

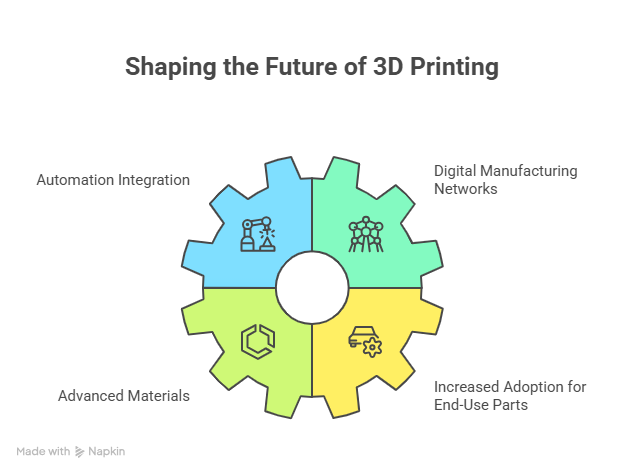

Future Trends in Production 3D Printing Services

Automation Integration

Automated material handling, post-processing, and quality control.

Digital Manufacturing Networks

Connected services for on-demand, distributed manufacturing (e.g., Xometry, Protolabs).

Advanced Materials

Expansion into composites, ceramics, and high-performance polymers.

Increased Adoption for End-Use Parts

Greater use in consumer goods, healthcare, and automotive production lines.

Cost Considerations

Cost Breakdown

Setup & DFM Review: Usually free or nominal for services.

Printing Costs: Based on volume, material, build time.

Post-Processing Costs: Surface treatment, dyeing, coating.

Shipping & Logistics: Depends on destination and batch size.

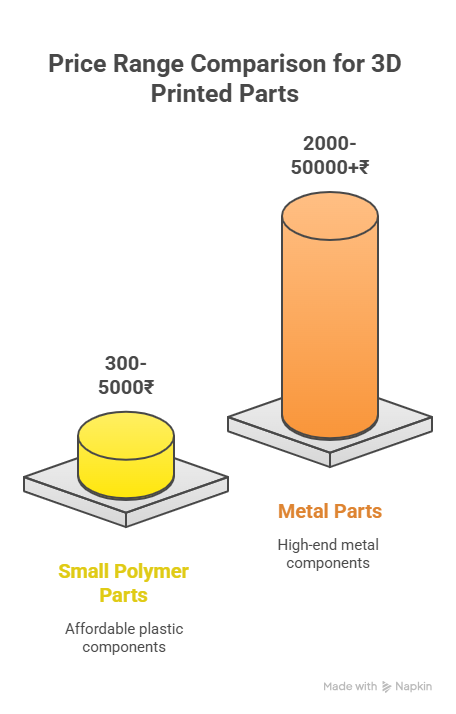

Typical Price Range

Small polymer parts: ₹300 to ₹5,000 per piece.

Metal parts: ₹2,000 to ₹50,000+ per piece.

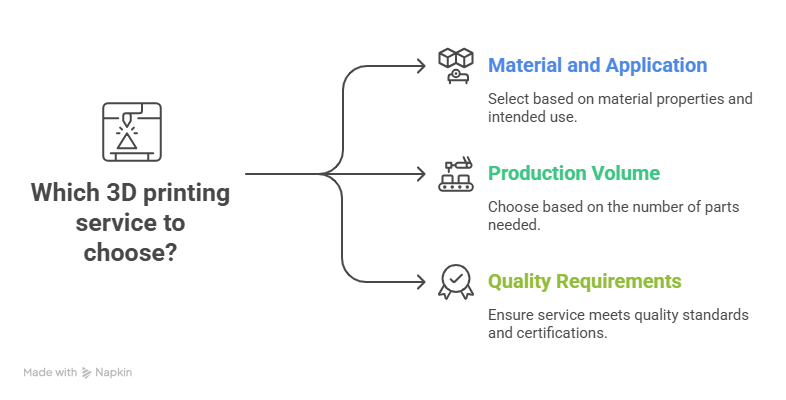

Choosing the Right Production 3D Printing Service

Based on Material and Application

Polymers: SLS, MJF for functional parts; SLA for detail.

Metals: DMLS, SLM for high strength and performance.

Based on Production Volume

Prototypes / Custom Parts: Single-run service.

Low-to-Mid Batch: Service with capacity for consistent repeatability.

Based on Quality Requirements

Services offering ISO certifications and quality control reports.

Tips for Using Production 3D Printing Services

Design for Additive Manufacturing (DFAM)

Optimize designs for efficiency, weight reduction, and cost savings.

Material Selection

Choose materials that match mechanical, thermal, and aesthetic requirements.

Validate with Prototypes First

Ensure designs function as intended before scaling to larger batches.

Ask for Certifications

Look for ISO 9001, AS9100, or medical ISO 13485 compliance depending on industry.

Conclusion

Production 3D Printing Services offer flexibility, speed, and innovation for companies looking to bypass traditional manufacturing constraints. From customized parts to functional prototypes and short-run production, these services provide a scalable path for bringing products to market faster with reduced risk.

Comments