Quick-Turn Molding: The Fast-Track Solution for Prototypes and Low-Volume Production

- shiva ganesh

- Jul 24

- 3 min read

Table Of Content

Introduction to Quick-Turn Molding

What is Quick-Turn Molding?

Quick-Turn Molding (also called rapid injection molding) is a specialized form of plastic injection molding designed to deliver fast lead times for low-volume production or prototypes. It prioritizes speed, cost-efficiency, and flexibility over the longevity of molds, using softer materials like aluminum for tooling and streamlined processes to reduce cycle times.

Quick-turn molding is ideal for companies needing functional prototypes, pilot runs, or bridge production between design validation and full-scale manufacturing.

A Brief History of Quick-Turn Molding

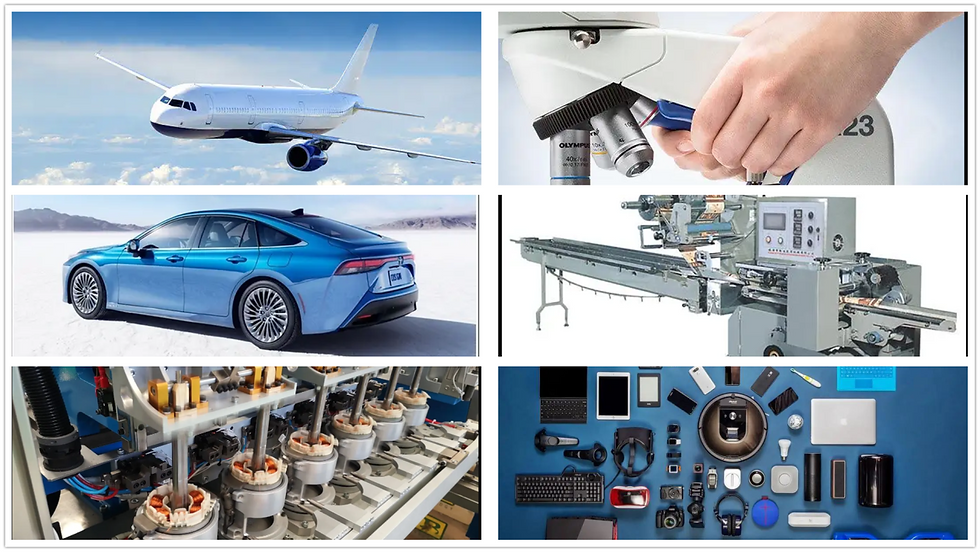

Emerging in the early 2000s, companies like Protolabs pioneered the concept to meet growing demand for faster prototyping solutions in industries such as medical devices, automotive, aerospace, and consumer electronics. Today, it remains a go-to service for agile manufacturing needs.

How Quick-Turn Molding Works

The Basic Workflow

Upload CAD files for instant quoting or rapid review.

DFM feedback is provided to optimize the part for molding.

Aluminum tooling is CNC machined quickly (typically within days).

Thermoplastic material is injected into the mold.

Parts are produced, inspected, and shipped within days to weeks.

Key Components of Quick-Turn Molding

Aluminum Molds

Faster to machine, less durable but perfect for low volumes.

Standardized Molding Presses

Machines tailored for rapid tool swaps and shorter cycles.

Optimized Workflow Software

Automates quoting, scheduling, and DFM analysis for speed.

Experienced Technicians

Focus on rapid iteration and fast turnaround.

Types of Quick-Turn Molding

Prototype Molding

Short runs for testing form, fit, and function.

Bridge Tooling

Temporary solution between prototyping and mass production.

Low-Volume Production

Ideal for hundreds to a few thousand parts.

Materials Used in Quick-Turn Molding

Common Thermoplastics

ABS

Polypropylene (PP)

Polycarbonate (PC)

Nylon (PA)

POM (Acetal)

TPU (Rubber-like plastics)

Limitations

Typically excludes exotic or specialty materials used in high-volume molds.

Applications of Quick-Turn Molding

Medical Devices

Enclosures, fixtures, housings for pilot testing.

Automotive

Concept parts, connectors, small batch components.

Consumer Products

Prototypes, limited runs for market testing.

Aerospace

Functional components for evaluation and fitment.

Electronics

Casings, connectors, mechanical components.

Advantages of Quick-Turn Molding

Speed

Parts delivered in as little as 7–21 days.

Cost-Effective for Small Batches

No need for expensive hardened steel tooling.

DFM Feedback

Rapid optimization of designs for manufacturability.

Flexibility

Allows design iterations before committing to full production.

Material Options

Access to a wide range of standard thermoplastics.

Limitations of Quick-Turn Molding

Limited Tool Life

Aluminum tools typically support 1,000–10,000 shots.

Tolerances

Not as tight as hardened steel tools, generally around ±0.1mm.

Surface Finish Options

Limited compared to production-grade tools (SPI A1 mirror finishes rare).

Not Suited for High-Volume

Per-part cost becomes inefficient beyond certain volumes.

Quick-Turn Molding vs. Traditional Injection Molding

Key Differences

Feature | Quick-Turn Molding | Traditional Molding |

Speed | 7–21 days | 8–16 weeks |

Tooling | Aluminum | Hardened Steel |

Volume | 100–10,000 parts | 10,000–1,000,000+ |

Tolerances | ±0.1mm | Tighter achievable |

Finish | Functional | High cosmetic options |

Cost (Tooling) | Lower | Higher |

Cost (Per Part) | Higher (small batch) | Lower (mass production) |

When to Choose Quick-Turn Molding

For prototypes, pilot production, or bridging gaps.

When speed is critical to project timelines.

For market validation and testing before committing to scale.

Future Trends in Quick-Turn Molding

AI-Driven Quoting & DFM

More accurate and faster quoting with design analysis.

Hybrid Molding Solutions

Integrating 3D-printed tooling with CNC molds for even faster turnaround.

Advanced Materials

Expanding options for short-run medical, aerospace, and electrical components.

Cost Considerations

Tooling Cost

Starting from ₹1–5 lakh for simple parts.

Production Cost

Economical up to 10,000 parts.

Higher per-part cost compared to high-volume molds.

Operational Costs

Lower due to simpler tooling and reduced maintenance.

Choosing the Right Quick-Turn Molding Partner

Based on Project Needs

Confirm expertise in rapid prototyping and small runs.

Ensure availability of DFM and engineering feedback.

Certifications

ISO 9001 for general manufacturing; ISO 13485 for medical components.

Value-Added Services

DFM analysis

Mold maintenance

Post-processing (painting, assembly)

Tips for Getting Started with Quick-Turn Molding

Design for Quick-Turn

Follow DFM guidelines for draft angles, wall thickness, and ejection.

Expect Iterations

Use quick-turn for refining designs rapidly.

Plan for Scaling

Consider how your bridge tooling aligns with long-term production.

Conclusion

Quick-Turn Molding bridges the gap between prototyping and mass production. It offers manufacturers a fast, reliable, and affordable way to bring designs to life with real materials and manufacturing processes, ensuring speed-to-market and design confidence.

Comments