Sheet Cutting: The Ultimate Guide to Precision Sheet Processing

- shiva ganesh

- Jul 29

- 4 min read

Table of Content

Introduction to Sheet Cutting

What is Sheet Cutting?

Sheet Cutting is a fundamental process within sheet metal fabrication and manufacturing, used to cut flat sheets of metal, plastic, or composite materials into specific shapes, sizes, and patterns. Sheet cutting serves as the starting point for further operations like bending, forming, or assembling.

Whether it's producing automotive panels, electronic enclosures, architectural elements, or industrial components, sheet cutting offers speed, precision, and repeatability.

A Brief History of Sheet Cutting Technology

Traditional sheet cutting methods like shearing and sawing evolved alongside industrialization. Modern CNC-controlled cutting technologies like laser cutting, plasma cutting, and waterjet cutting emerged in the late 20th century, allowing for complex geometries and high precision in both prototyping and mass production.

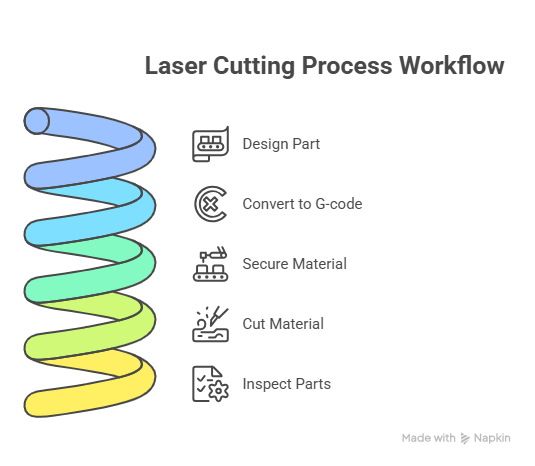

How Sheet Cutting Works

The Basic Workflow

Design the part or pattern in CAD software.

Convert design files into machine-readable code (G-code).

Secure the sheet on the machine bed.

Cut the material using the chosen cutting technology.

Inspect the cut parts for accuracy and quality.

Key Sheet Cutting Technologies

Laser Cutting

Uses a high-powered laser beam to melt, burn, or vaporize material with extreme precision.

Plasma Cutting

Utilizes a plasma torch to cut through electrically conductive materials like steel and aluminum.

Waterjet Cutting

Employs a high-pressure stream of water mixed with abrasive particles to cut virtually any material without heat.

Shearing

Mechanical cutting process using blades to make straight cuts in sheet materials.

Punching

Uses CNC turret punches to create holes and complex patterns by mechanically stamping the sheet.

Sheet Cutting Processes

Laser Cutting

High precision and speed

Suitable for thin to medium thickness metals and plastics

Ideal for complex shapes and fine details

Plasma Cutting

Fast and cost-effective for thicker metals

Common in fabrication shops and heavy industries

Waterjet Cutting

No heat-affected zone (HAZ)

Cuts metals, composites, ceramics, glass, and plastics

Shearing

Straight cuts only

High-speed production for simple geometries

Punching

Ideal for repetitive shapes, holes, and patterns

Fast and efficient for high-volume production

Materials Used in Sheet Cutting

Common Materials

Metals

Steel, stainless steel, aluminum, copper, brass, titanium.

Plastics

Acrylic, polycarbonate, PVC, ABS.

Composites

Carbon fiber, fiberglass.

Others

Foam, rubber, and specialized industrial laminates.

Applications of Sheet Cutting

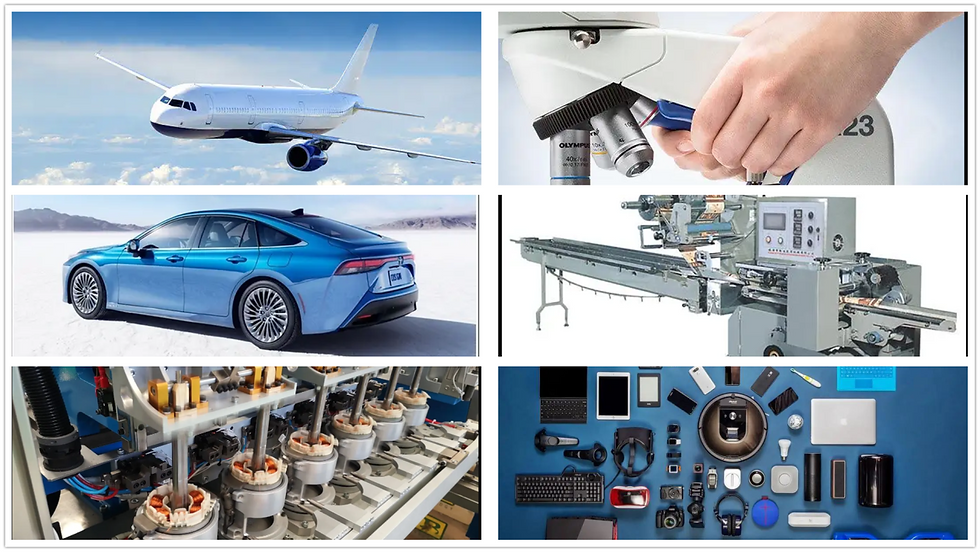

Automotive

Chassis components, panels, brackets.

Aerospace

Precision parts, structural panels, interior components.

Electronics

Enclosures, faceplates, heat sinks.

Architecture

Decorative panels, cladding, structural components.

Industrial Equipment

Machine guards, conveyors, control panels.

Signage

Letters, logos, intricate patterns.

Advantages of Sheet Cutting

Precision and Repeatability

CNC-controlled processes ensure high accuracy and consistency.

Flexibility

Suitable for prototypes through mass production.

Wide Material Range

Cuts metals, plastics, composites, and more.

Complex Geometries

Capable of producing intricate shapes and internal features.

Speed

Modern cutting machines enable fast turnaround times.

Limitations of Sheet Cutting

Thickness Limits

Some processes (laser, punching) are limited by material thickness.

Edge Quality

Plasma and mechanical methods may require secondary finishing.

Heat Effects

Laser and plasma cutting may create heat-affected zones in some materials.

Initial Setup Costs

Machines and tooling can represent a significant investment.

Sheet Cutting vs. Other Fabrication Processes

Key Differences

Feature | Sheet Cutting | CNC Machining | 3D Printing |

Material Form | Flat sheets | Solid blocks | Filament/powder |

Geometry | 2D or flat-based 3D | 3D complex parts | Fully 3D |

Volume | Low to high | Low to medium | Low to medium |

Speed | Fast (after setup) | Moderate | Slow per part |

Edge Finish | Varies by process | High | Moderate |

When to Choose Sheet Cutting

For flat, panel-like components.

When speed, volume, and material efficiency are priorities.

Ideal for simple to moderately complex profiles.

Future Trends in Sheet Cutting

Fiber Laser Technology

Improved speed, precision, and energy efficiency for cutting metals.

Automation and Integration

Fully automated systems combining cutting, sorting, and stacking.

AI and Smart Manufacturing

Adaptive software optimizing toolpaths, energy use, and nesting.

Hybrid Machines

Combining cutting, punching, and bending in a single machine.

Cost Considerations

Machine Cost

Laser cutters: ₹30 lakhs to ₹2 crores+

Plasma cutters: ₹10 lakhs to ₹50 lakhs

Waterjets: ₹50 lakhs to ₹3 crores

Shears & punches: ₹5 lakhs to ₹1 crore

Operational Costs

Energy consumption (especially for lasers and waterjets)

Consumables (nozzles, abrasives, gases)

Maintenance and skilled labor

Part Cost

Depends on material, thickness, complexity, and volume.

Choosing the Right Sheet Cutting Technology

Based on Material

Metals: Laser, plasma, waterjet.

Plastics/composites: Laser, waterjet.

Foams, rubbers: Waterjet or knife cutting.

Based on Application

Fine detail: Laser.

Thicker sections: Plasma or waterjet.

High-volume, repetitive: CNC punching.

Tips for Getting Started with Sheet Cutting

Material Knowledge

Understand the cutting behavior and properties of your materials.

Optimize Nesting

Efficient layout minimizes waste and cost.

Use the Right Technology

Match cutting method to material, thickness, and quality needs.

Work with Experts

Partner with established cutting service providers for best results.

Conclusion

Sheet Cutting remains a foundational process in modern manufacturing, enabling fast, precise, and flexible production of components across industries. Whether through laser, plasma, waterjet, or punching, this technology is essential for turning flat materials into finished products with accuracy and efficiency.

Comments