Waterjet Cutting: The Ultimate Guide to Cold Cutting Technology

- shiva ganesh

- Jul 28

- 4 min read

Table Of Content

Introduction to Waterjet Cutting

What is Waterjet Cutting?

Waterjet Cutting is a highly versatile cold cutting process that uses a high-pressure stream of water, often mixed with an abrasive like garnet, to cut through a wide range of materials. Unlike thermal cutting methods, waterjet cutting produces no heat-affected zones (HAZ), making it ideal for materials sensitive to heat.

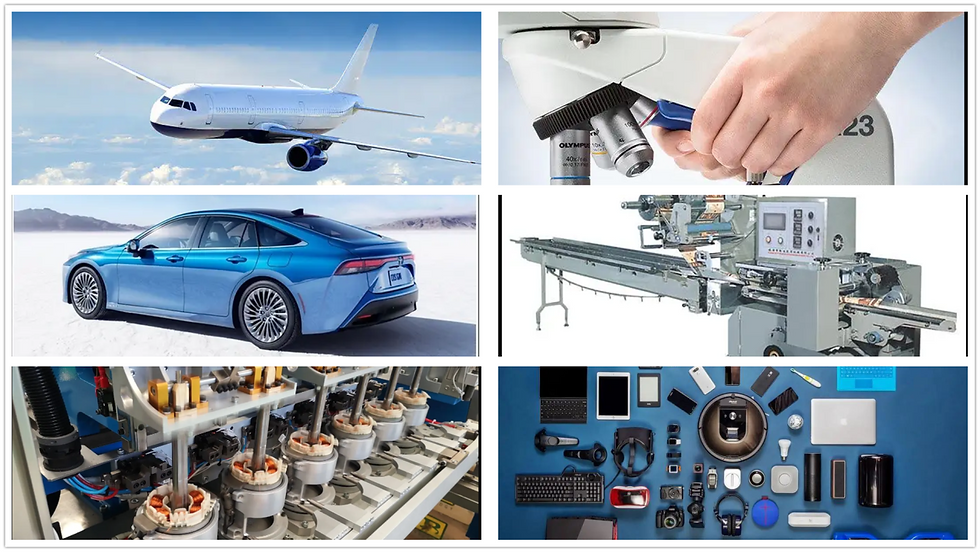

Waterjet cutting is popular in industries requiring precision, material integrity, and the ability to cut diverse materials, such as aerospace, automotive, defense, medical devices, architecture, and heavy industries.

A Brief History of Waterjet Cutting

Waterjet cutting technology emerged in the 1970s for soft materials and evolved in the 1980s with abrasive jets capable of cutting hard materials like steel, stone, and ceramics. Today, waterjet systems are crucial in advanced manufacturing and precision fabrication.

How Waterjet Cutting Works

The Basic Workflow

Design the part using CAD software.

Convert the design into machine-readable G-code via CAM software.

Load the material on the waterjet bed.

Pressurize water up to 60,000–90,000 psi using a hydraulic pump.

Inject abrasive material (if required) into the high-pressure water stream.

Cut the material following precise toolpaths.

Inspect the finished part for quality and accuracy.

Key Components of a Waterjet Cutter

High-Pressure Pump

Generates ultra-high-pressure water for cutting.

Cutting Head

Converts pressurized water into a precise, high-velocity stream through a ruby or diamond nozzle.

Abrasive Feeder

Introduces abrasive materials (typically garnet) for cutting harder substances.

Catcher Tank

Dampens the energy of the waterjet after cutting.

CNC Controller

Guides the cutting head along the programmed path with extreme accuracy.

Waterjet Cutting Processes

Pure Waterjet Cutting

Uses only high-pressure water. Ideal for soft materials:

Rubber

Foam

Plastics

Food

Abrasive Waterjet Cutting

Adds abrasive particles to the water stream for harder materials:

Metals

Stone

Ceramics

Composites

Glass

Materials Used in Waterjet Cutting

Common Materials

Metals

Steel, stainless steel, aluminum, titanium, brass, copper.

Non-Metals

Rubber, plastics, composites, ceramics, glass, wood, stone.

Special Materials

Foam, carbon fiber, laminates, granite, marble.

Applications of Waterjet Cutting

Aerospace

Precision components, turbine parts, structural panels.

Automotive

Chassis parts, interiors, gaskets, heat shields.

Architecture

Decorative panels, stone inlays, glass elements.

Medical Devices

Instruments, implants, prosthetic parts.

Defense

Armor plating, structural components, prototype parts.

Art and Design

Signage, sculptures, intricate patterns.

Advantages of Waterjet Cutting

No Heat-Affected Zone (HAZ)

Preserves material integrity and mechanical properties.

Versatility

Cuts virtually any material without tool changes.

Precision

Achieves tolerances of ±0.1mm to ±0.2mm, depending on thickness.

Complex Geometries

Handles intricate shapes and internal features.

Eco-Friendly

Uses water and natural abrasives; no hazardous fumes or dust.

Limitations of Waterjet Cutting

Slower than Thermal Cutting

Cutting speed is generally slower than laser or plasma for thin materials.

Operational Costs

Abrasives, water consumption, and pump maintenance add to costs.

Thickness Constraints

Excellent for thick materials but less efficient for extremely thin sheets compared to lasers.

Surface Finish

Produces a textured edge (striation lines) on thicker materials; may require secondary finishing.

Waterjet Cutting vs. Other Cutting Methods

Key Differences

Feature | Waterjet Cutting | Laser Cutting | Plasma Cutting | CNC Routing |

Heat Affected | None | Yes (HAZ) | Yes (HAZ) | Minimal |

Material Range | Almost any material | Metals, non-metals | Metals only | Non-metals, soft |

Precision | High (±0.1mm) | Very High (±0.05mm) | Moderate | Moderate |

Thickness | Very thick possible | Up to 20-25mm | Thick metals | Limited |

Cost | High (operation) | Moderate to High | Lower | Moderate |

When to Choose Waterjet Cutting

For materials sensitive to heat.

When cutting thick or composite materials.

For intricate designs on non-metals or exotic materials.

Future Trends in Waterjet Cutting

Higher Pressure Systems

Advancements toward 100,000 psi+ pumps for faster, more efficient cutting.

Automation Integration

Robotic arms and CNC automation for streamlined production lines.

Intelligent Software

AI-driven toolpath optimization and material management.

Hybrid Systems

Combining waterjet with other technologies for flexible manufacturing.

Cost Considerations

Machine Cost

Basic systems: ₹50 lakhs – ₹1 crore+

Advanced multi-axis systems: ₹1 crore – ₹3 crores+

Operational Costs

Abrasive garnet (consumable)

Water and energy usage

Pump maintenance and parts replacement

Part Cost

Higher than laser/plasma but justified for special materials and no-heat applications.

Choosing the Right Waterjet System

Based on Material

Pure water: Soft materials like rubber, foam.

Abrasive water: Hard materials like metals, stone.

Based on Application

Fine detail: 3-axis or 5-axis systems.

Large parts: Large-bed waterjet machines.

Volume Consideration

Best for low to medium production, prototypes, and custom work.

Tips for Getting Started with Waterjet Cutting

Optimize Design for Waterjet

Avoid sharp internal corners; use radiuses to extend nozzle life.

Understand Taper Compensation

Software helps reduce the natural taper of the waterjet cut.

Maintain Regularly

Clean nozzles, replace seals, and monitor pump performance.

Partner with Experts

Work with experienced service providers for critical projects.

Conclusion

Waterjet Cutting delivers unmatched versatility in modern manufacturing, capable of cutting virtually any material with high precision and no thermal impact. From aerospace components to architectural masterpieces, waterjet cutting enables creativity and accuracy without compromise.

Comments