Wire EDM Machining: The Ultimate Guide to Precision Electrical Discharge Machining

- shiva ganesh

- Jul 23

- 4 min read

Updated: Jul 30

Table Of Content

Introduction to Wire EDM Machining

What is Wire EDM?

Wire EDM (Electrical Discharge Machining) is a non-traditional machining process that uses a thin, electrically charged wire to cut complex shapes and intricate contours in electrically conductive materials. Instead of physically cutting the material, Wire EDM uses controlled electrical discharges (sparks) to erode the material precisely.

Wire EDM is renowned for achieving tight tolerances, intricate geometries, and superior surface finishes in hard materials like tool steels, titanium, and tungsten carbide.

A Brief History of EDM Technology

The EDM process was developed in the 1940s for precision machining of hard materials that were difficult to machine with traditional tools. Wire EDM, specifically, gained popularity in the 1970s and 1980s with the advent of computer-controlled systems, revolutionizing the manufacturing of precision components in aerospace, medical, and tooling industries.

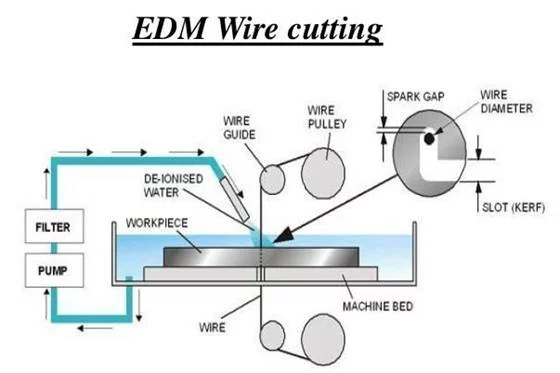

How Wire EDM Works

The Basic Workflow

Design the part in CAD software.

Program the cutting path in CAM software.

Setup the workpiece submerged in a dielectric fluid.

Cut using a continuously fed thin wire (typically brass or zinc-coated) charged with electrical current.

Rinse and inspect for precision and finish.

Key Components of Wire EDM Machines

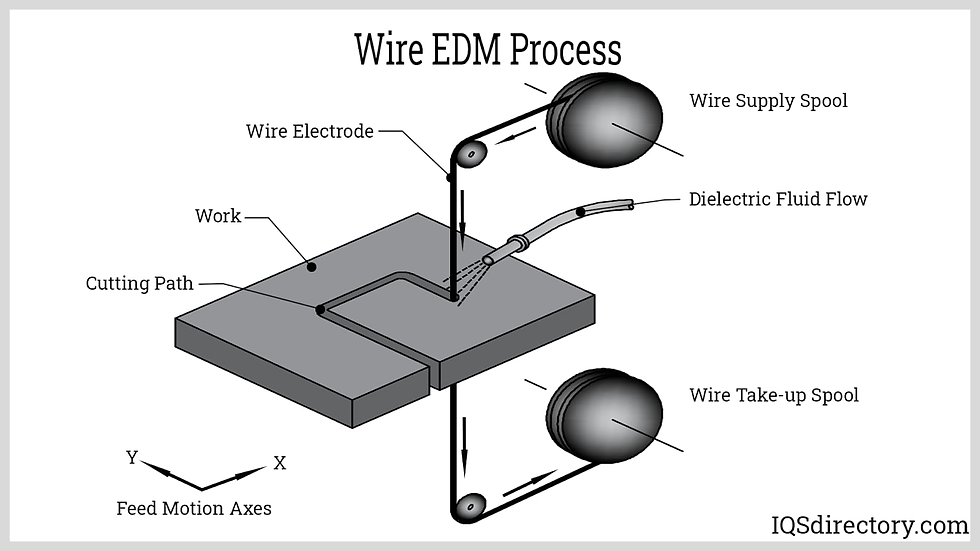

Wire Electrode

A fine brass or coated wire (typically 0.1–0.3mm diameter) serves as the cutting tool.

Workpiece

Must be electrically conductive (metals, alloys, conductive ceramics).

Dielectric Fluid

Usually deionized water to control the discharge, cool the workpiece, and flush debris.

Power Supply

Generates controlled electrical pulses for precise material removal.

Servo Control System

Maintains a consistent gap between wire and workpiece.

Wire EDM Machining Process

Spark Erosion Cutting

Electric discharges occur between the wire and the workpiece in the dielectric fluid, causing localized melting and vaporization. The wire never contacts the workpiece physically.

Continuous Wire Feeding

The wire is continuously fed through the system to maintain cutting precision and avoid breakage.

Multi-Axis Movement

Modern EDM machines operate on CNC-controlled X, Y, U, V axes for complex tapers and shapes.

Materials Used in Wire EDM

Commonly Machined Materials

Tool Steels (D2, H13, A2)

For molds, dies, and tooling inserts.

Stainless Steels (304, 316, 17-4PH)

For medical devices, aerospace, and precision components.

Titanium

Aerospace and medical implants.

Carbides

Punches, dies, and wear components.

Aluminum Alloys

Used occasionally where precision is more critical than speed.

Inconel & Super alloys

High-temperature, corrosion-resistant applications.

Copper, Brass

For electrical components.

Applications of Wire EDM

Aerospace

Turbine components, fixtures, and precision tooling.

Medical Devices

Orthopedic implants, surgical tools, fine instrumentation.

Tooling & Die Making

Injection molds, extrusion dies, blanking dies.

Automotive

High-precision engine and transmission components.

Electronics

Precision connectors, lead frames, intricate geometries.

Defense

Complex components in hardened alloys.

Advantages of Wire EDM

Precision Cutting

Tolerances up to ±0.002 mm, ideal for detailed, intricate work.

Complex Geometries

Cuts sharp corners, intricate contours, and thin walls unattainable by other methods.

Material Hardness Irrelevant

Cuts the hardest materials with ease.

No Tool Wear

Since the wire doesn't physically contact the workpiece, no mechanical force is applied.

Superior Surface Finish

Achieves fine surface finishes (Ra 0.1–0.4μm).

Limitations of Wire EDM

Conductive Materials Only

Non-conductive materials cannot be machined.

Slower than Conventional Methods

EDM is slower than CNC milling for simple shapes.

Wire Costs

Continuous wire feed results in material waste (wire discarded after use).

Requires Submersion

Workpiece must be submerged in dielectric fluid, limiting part size.

Wire EDM vs. Other Machining Technologies

Key Differences

Feature | Wire EDM | CNC Milling | Laser Cutting | Waterjet Cutting |

Contact | No physical contact | Cutting tool contacts | Laser energy | High-pressure water |

Materials | Conductive only | Almost all materials | Conductive / non-conductive | Almost all materials |

Tolerance | ±0.002 mm | ±0.01 mm | ±0.1 mm | ±0.1 mm |

Surface Finish | Excellent (mirror-like) | Good (depends on tool) | Good (burnt edges) | Moderate |

Speed | Slow | Fast | Fast | Moderate |

Complexity | Very High | Medium-High | Medium | Medium |

When to Choose Wire EDM

For intricate, high-precision parts in hard metals.

When tight tolerances, complex internal cuts, or sharp corners are required.

For tooling and die-making.

Future Trends in Wire EDM

Automation Integration

Combining Wire EDM with robotic handling and multi-machine setups for lights-out manufacturing.

Improved Wire Technology

Development of coated wires for faster cuts and finer finishes.

AI-Powered Process Control

Adaptive software optimizing cutting speed, wire tension, and pulse settings in real time.

Expanded Materials

Research into adapting EDM-like technologies for more advanced conductive materials.

Cost Considerations

Machine Cost

Ranges from ₹25 lakhs to ₹2 crores depending on precision, size, and features.

Operational Costs

Wire: Brass or zinc-coated, consumed continuously.

Dielectric fluid: Maintenance and replacement.

Power: Higher than conventional CNC.

Labor: Skilled operators required.

Part Cost

Small components: ₹500 to ₹20,000+ per piece depending on complexity and material.

Choosing the Right Wire EDM Setup

Based on Material

Ideal for hardened steels, titanium, carbides, and superalloys.

Based on Application

Best for precision tooling, aerospace components, and medical parts.

Avoid for non-conductive or simple shapes better suited for milling.

Tips for Getting Started with Wire EDM

Understand the Material

Ensure the material is conductive and suitable for EDM.

Design for EDM

Incorporate start holes, flush paths, and avoid blind cavities where possible.

Maintain Fluid Quality

Keep dielectric fluid clean and properly filtered for consistent results.

Leverage Expertise

Work with experienced operators and well-maintained machines for optimal outcomes.

Conclusion

Wire EDM stands as the gold standard for precision machining of conductive materials. It offers unmatched accuracy, complexity, and surface quality for industries where performance is non-negotiable. While not the fastest, its capabilities in tooling, aerospace, and medical manufacturing make it irreplaceable.

Comments