CNC Milling: A Comprehensive Guide

- Bhargava Krishna Marripati

- Jul 21

- 5 min read

Updated: Jul 23

CNC milling is a subtractive manufacturing technique that involves a computer-controlled rotating cutting tool removing material from a workpiece to form a specific shape. This versatile process is employed to produce a diverse array of parts and products across different industries.

Table of Contents

Introduction to CNC Milling

What is CNC Milling?

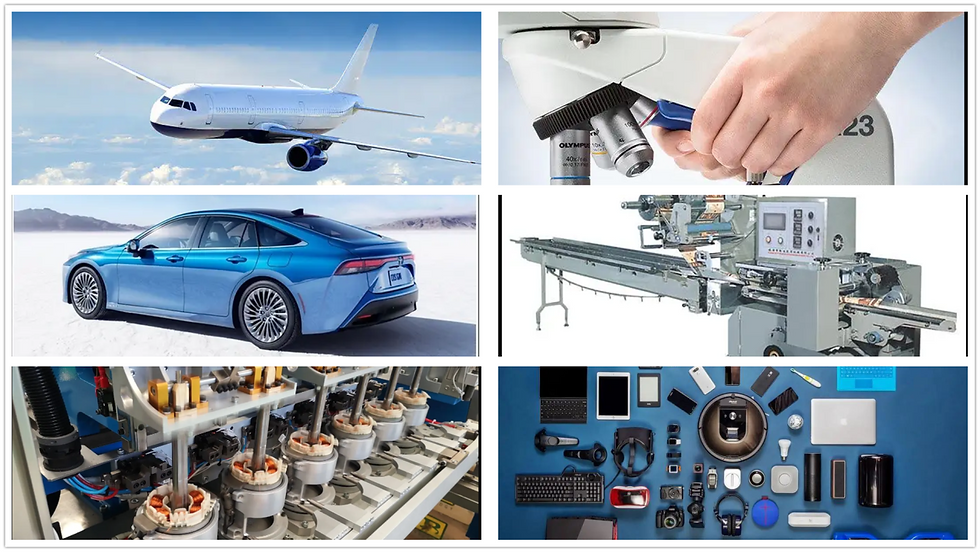

CNC Milling is a computer-controlled machining process where rotating cutting tools remove material from a stationary workpiece. It’s a core subtractive manufacturing technique used to shape metals, plastics, and more into precise parts. From aerospace to consumer products, CNC milling is behind some of the most critical components you use every day.

How it Differs from Other CNC Processes

Unlike CNC turning (where the part spins) or EDM (where sparks shape the material), milling works by rotating the cutting tool. This makes it versatile—perfect for 2D contours, 3D forms, and everything in between.

The Mechanics of CNC Milling

Axis Movements Explained (3-Axis to 5-Axis)

3-Axis Milling – Basic movement along X, Y, and Z axes. Great for flat surfaces and simple profiles.

4-Axis Milling – Adds rotation on one axis (A or B), allowing side machining.

5-Axis Milling – Full rotation and tilt, enabling complex geometries and undercuts.

Types of Milling Operations

Face Milling

The cutting tool faces down and removes material across the surface. Ideal for flat surfaces and finishing operations.

Peripheral Milling

The tool cuts along the edge of the workpiece—great for deep grooves and profiles.

Slot Milling

Used to cut slots and keyways with high accuracy.

Pocket Milling

Removes material from within a closed boundary—common in mold cavities and housings.

Similarly there are many milling operations including Plain Milling, Side Milling, Straddle Milling, Angular Milling, Gang Milling, Form Milling, Profile Milling, End Milling, Saw Milling, Milling Keyways, Grooves, and Slot, Gear Milling, Helical Milling, Cam Milling, Thread Milling

CNC Milling Machines

Vertical Milling Machines

These have a vertically oriented spindle. They’re compact, user-friendly, and widely used in small shops and prototyping.

Horizontal Milling Machines

Here, the spindle lies horizontally, offering better chip evacuation and support for heavy-duty cutting.

Gantry Milling Machines

Massive machines where the tool moves over a stationary workpiece. Used for aerospace and large-scale parts.

5-Axis Milling Machines

The ultimate in flexibility—these machines can approach a part from almost any direction, reducing setups and improving quality.

Tooling in CNC Milling

Types of Cutting Tools

End Mills – Versatile tools for contouring, slotting, and profiling.

Ball Nose Cutters – Ideal for 3D surfacing.

Face Mills – Used for quick material removal on flat surfaces.

Tool Holding Systems

Common holders include ER collets, hydraulic chucks, and shrink-fit systems—each with its advantages in precision and stability.

Tool Wear and Maintenance

Regular inspection and replacement of tools prevent poor surface finish and tool breakage. Tool life depends on material, cutting speed, and coolant use.

Materials Used in CNC Milling

Metals

Aluminum – Lightweight, easy to machine.

Steel – Strong and durable, used for structural parts.

Titanium – Tough but tricky—used in aerospace and medical.

Plastics

Delrin (POM) – Low friction and high stiffness.

Nylon – Durable, slightly flexible.

Polycarbonate – Strong and impact-resistant.

Specialty Materials

Graphite for EDM electrodes.

Composites for lightweight, high-strength components.

Software and Programming in CNC Milling

CAD/CAM Integration

CAD (Computer-Aided Design) helps design the part, while CAM (Computer-Aided Manufacturing) converts the model into toolpaths for the milling machine.

G-Code for Milling

G-code commands tell the machine where to move, how fast to spin the tool, and when to make cuts. A typical code looks like:G01 X25 Y15 F100 – Move to X25 Y15 at a feed rate of 100 mm/min.

Toolpath Strategies

Zigzag (Raster) Milling – Good for clearing material.

Contour Milling – Follows part geometry for finish passes.

Trochoidal Milling – Reduces tool load for hard materials.

Applications of CNC Milling

Aerospace and Automotive

Turbine blades, engine components, brackets, and housings—precision is paramount.

Die and Mold Making

Milling creates the intricate cavities and cores needed for injection molds and stamping dies.

Consumer Electronics

Phone frames, speaker grilles, and laptop chassis often come from aluminum milling.

Rapid Prototyping

Startups and R&D teams use CNC milling to validate designs quickly and accurately.

Benefits of CNC Milling

High Precision and Accuracy

You can machine parts with tolerances tighter than ±0.01 mm—perfect for tight-fit assemblies.

Scalability for Production

From one-off prototypes to thousands of identical parts, CNC milling is built for scalability.

Complex Geometries Made Simple

Undercuts, curves, and contours are easy with multi-axis milling.

Limitations and Challenges

Setup Time

Clamping, tool selection, and programming can take time, especially for complex parts.

Machine and Tooling Costs

High-end 5-axis machines and carbide tools come with steep price tags.

Operator Skill Requirements

Skilled CNC programmers and machinists are essential for efficient operations.

CNC Milling vs. Manual Milling

Speed and Efficiency

CNC wins hands down. Programs can run 24/7 with minimal supervision.

Quality and Consistency

Manual milling is subject to human error. CNC offers repeatable perfection.

Automation Capabilities

CNC milling supports automation with tool changers, probes, and robotic arms.

Emerging Trends in CNC Milling

High-Speed Machining

Cutting at extreme RPMs with minimal tool wear. More speed, less time.

Hybrid Manufacturing

Combining milling with additive processes like 3D printing for the best of both worlds.

AI and Predictive Maintenance

Smart sensors detect tool wear, machine vibration, and predict failures before they happen.

Getting Started with CNC Milling

Learning Resources

Online Courses – Udemy, Coursera, LinkedIn Learning

Books – “The CNC Cookbook” and “CNC Milling in the Workshop”

Communities – Reddit’s r/CNC, Practical Machinist forum

Entry-Level Machines

Benchtop CNC mills like the Pocket NC or Tormach PCNC are perfect for hobbyists and startups.

Common Mistakes to Avoid

Skipping tool calibration

Incorrect feed rates

Poor fixturing and work holding

Conclusion

CNC milling is not just a manufacturing process—it’s an enabler of modern innovation. Whether you're building jet engines or jewelry, the precision, speed, and versatility of CNC milling make it an essential tool for engineers, designers, and manufacturers alike.

FAQs on CNC Milling

1. What’s the difference between CNC milling and CNC turning?

Milling uses a rotating tool on a stationary part, while turning rotates the part against a stationary tool.

2. How accurate is CNC milling?

With the right setup, CNC mills can achieve tolerances as tight as ±0.01 mm.

3. Is CNC milling expensive to get started?

Initial costs can be high, but desktop CNC mills offer a budget-friendly way to begin.

4. Can CNC mills cut any material?

Almost. From soft plastics to hardened steel and titanium, the right tooling can handle it.

5. What software is used in CNC milling?

Fusion 360, SolidWorks CAM, Mastercam, and Autodesk HSM are popular choices.

Comments