HP Multi Jet Fusion (MJF): The Ultimate Guide to Industrial 3D Printing

- shiva ganesh

- Jul 31

- 4 min read

Table of Contents

Introduction to HP Multi Jet Fusion

What is HP Multi Jet Fusion (MJF)?

HP Multi Jet Fusion (MJF) is an advanced powder bed fusion additive manufacturing technology developed by Hewlett-Packard (HP) for producing high-quality plastic parts. It is widely recognized for delivering excellent mechanical properties, fine details, and smooth surface finishes faster and more efficiently than traditional 3D printing methods like SLS (Selective Laser Sintering).

MJF is commonly used for functional prototypes, small to medium batch production, and end-use parts in industries like automotive, healthcare, and consumer goods.

A Brief History of HP Multi Jet Fusion Technology

HP launched Multi Jet Fusion in 2016, introducing it as a faster, more cost-efficient alternative to SLS and SLA for polymer parts. Over the years, MJF technology has become synonymous with production-grade 3D printing for plastics, capable of delivering parts with isotropic properties and superior detail resolution.

How HP Multi Jet Fusion Works

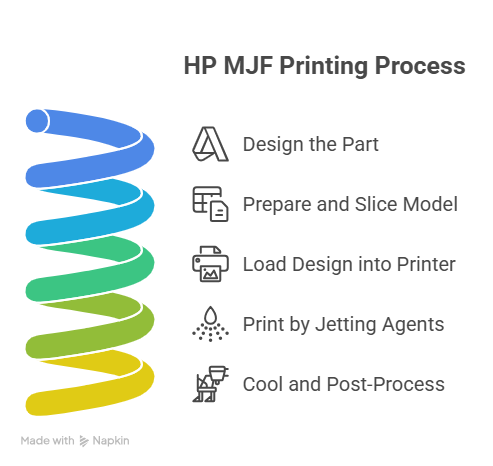

The Basic Workflow

Design the part using CAD software.

Prepare and slice the model using HP’s proprietary software tools.

Load the design into the HP MJF printer.

Print by jetting agents onto a bed of powder and fusing layers with heat.

Cool and post-process the parts (depowdering, dyeing, or surface smoothing).

Key Components of HP MJF Printers

Print Head Arrays

Spray agents (fusing and detailing) selectively across the powder bed.

Powder Bed / Build Unit

Distributes fine plastic powder evenly layer-by-layer.

Fusing Lamps

Apply heat to fuse areas where agents have been jetted.

Control System

Monitors precision, heat control, and consistency throughout the process.

Types of HP MJF Printers

HP Jet Fusion 5200 Series

Industrial-scale for high productivity and end-use parts.

HP Jet Fusion 4200 Series

Ideal for functional prototyping and small-batch manufacturing.

HP Jet Fusion 540/580 Series (Color 3D Printing)

Enables full-color 3D printing for detailed prototypes and presentation models.

HP Multi Jet Fusion Process

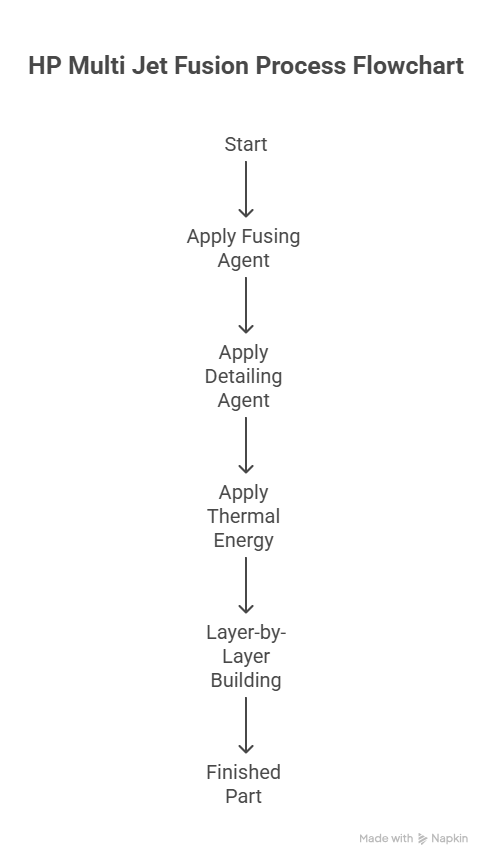

Powder Bed Fusion with Agent-Based Fusion

Unlike SLS, MJF uses fusing and detailing agents applied via inkjet heads, followed by thermal energy to create the part.

Fusing Agent: Darkens areas to absorb heat and fuse material.

Detailing Agent: Inhibits fusing for sharp edges and finer details.

The process builds parts layer-by-layer within a bed of fine polyamide powder.

Materials Used in HP MJF

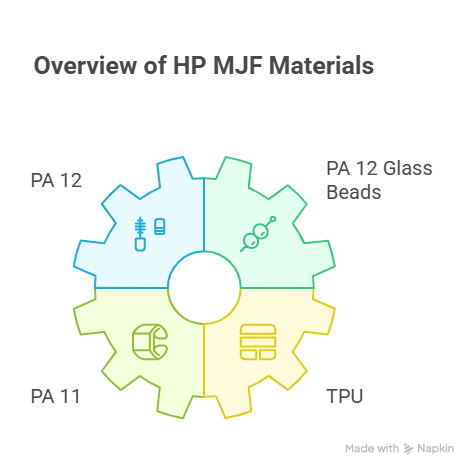

Nylon-Based Polymers (Polyamides)

PA 12 (Nylon 12)

Strong, lightweight, ideal for functional parts.

PA 12 Glass Beads

Enhanced stiffness and dimensional stability.

PA 11 (Bio-Based Nylon 11)

Tougher, more ductile, used for impact-resistant parts.

TPU (Thermoplastic Polyurethane)

Flexible, elastic for soft-touch components.

Applications of HP Multi Jet Fusion

Aerospace & Automotive

Functional components, housings, ducting, and lightweight parts.

Medical Devices

Orthopedic tools, prosthetics, and anatomical models.

Consumer Goods

Wearables, sports equipment, eyewear, and electronic housings.

Industrial Tooling

Jigs, fixtures, custom brackets, and short-run manufacturing tools.

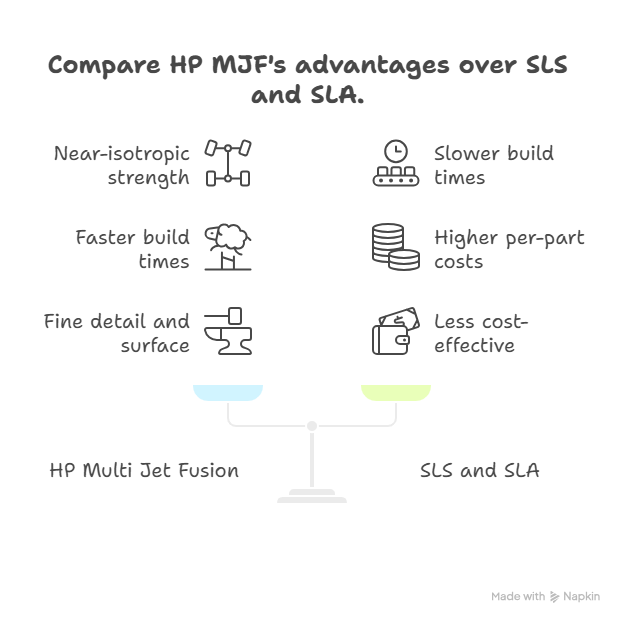

Advantages of HP Multi Jet Fusion

High-Quality Mechanical Properties

Produces parts with near-isotropic strength suitable for end-use applications.

Exceptional Speed and Productivity

Faster build times compared to SLS and SLA, especially for batch production.

Fine Detail and Surface Quality

Sharper edges, smoother finishes due to detailing agents.

Cost-Effective for Medium Volumes

Reduces per-part costs with high packing density and fast cycle times.

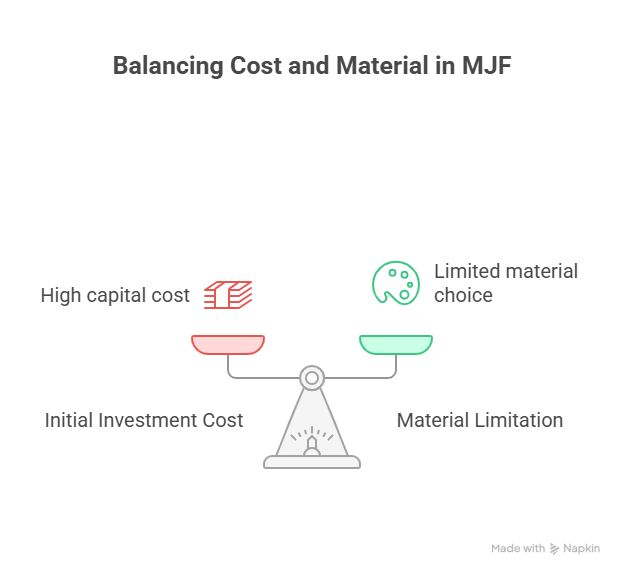

Limitations of HP Multi Jet Fusion

Initial Investment Cost

High capital cost for printers and post-processing equipment.

Powder Management

Requires dedicated processes for powder handling, sieving, and recycling.

Surface Porosity

May require post-processing (e.g., vapor smoothing, dyeing) for a sealed surface.

Material Limitation

Primarily focused on Nylon-based polymers and TPU.

HP MJF vs. Other 3D Printing Technologies

Key Differences

Feature | HP MJF | SLS | FDM |

Process | Powder + Agents | Powder + Laser | Filament extrusion |

Speed | Faster per batch | Slower per batch | Slow, layer-by-layer |

Strength | Isotropic | Strong, anisotropic | Anisotropic |

Surface Finish | Smoother, detailed | Coarse | Visible layers |

Best Use | Functional parts | Functional parts | Prototypes, simple parts |

When to Choose HP MJF

For functional prototypes needing high strength and accuracy.

For small to medium production runs of complex parts.

For parts requiring good aesthetics and dimensional consistency.

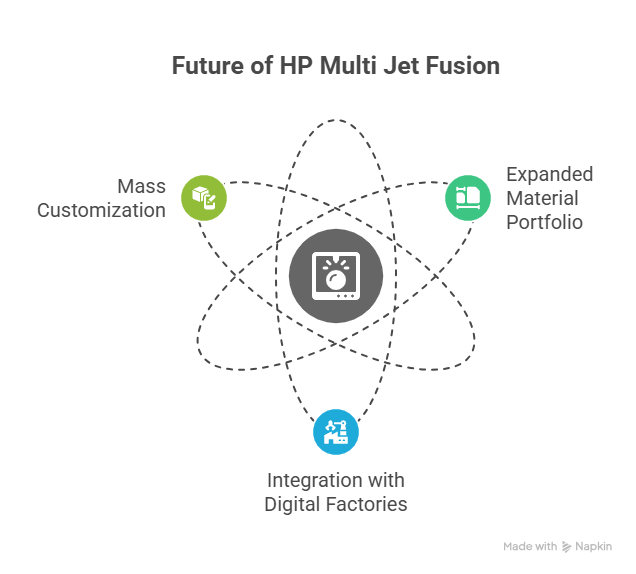

Future Trends in HP Multi Jet Fusion

Expanded Material Portfolio

New polymers, composites, and elastomers are expanding beyond nylon and TPU.

Integration with Digital Factories

Automated workflows combining MJF with AI and Industry 4.0 systems.

Mass Customization

Scalable solutions for personalized products in medical, automotive, and consumer goods.

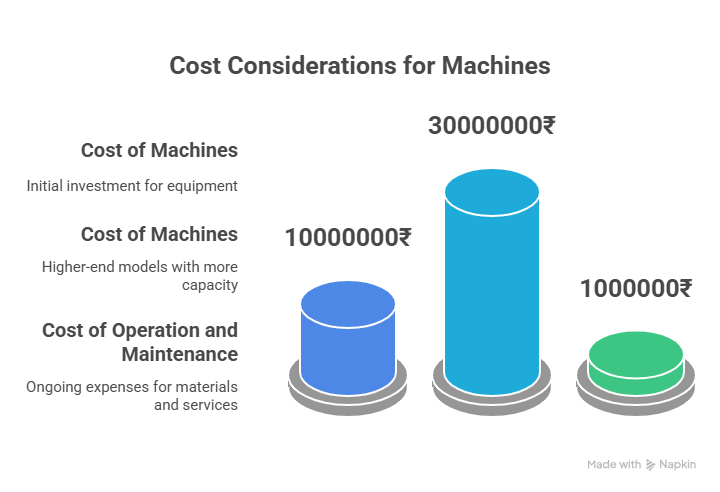

Cost Considerations

Cost of Machines

Starts around ₹1 crore to ₹3 crores depending on model and capacity.

Cost of Operation and Maintenance

Includes material costs (nylon powders), post-processing equipment, service contracts, and energy.

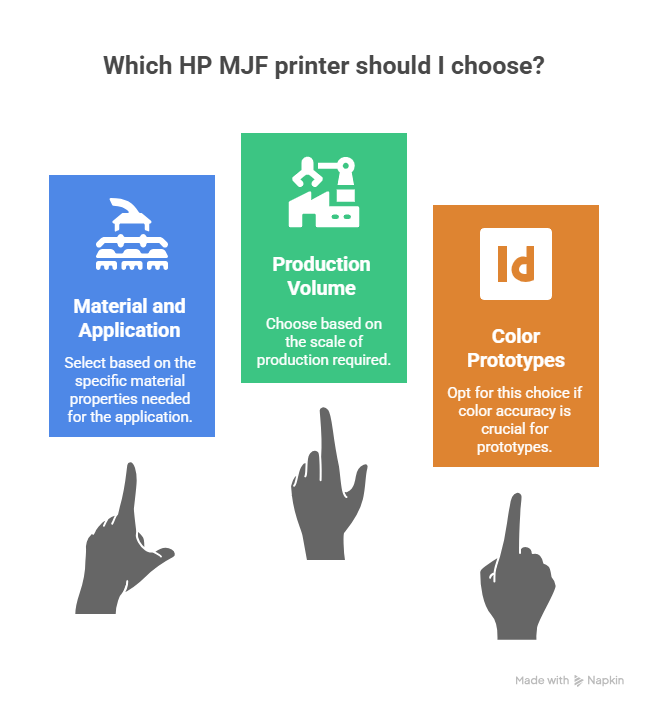

Choosing the Right HP MJF Printer

Based on Material and Application

PA 12: General-purpose functional parts

PA 11: Impact-resistant components

TPU: Flexible, soft-touch applications

Based on Production Volume

Low to medium volume: HP Jet Fusion 4200

High volume: HP Jet Fusion 5200

Color prototypes: HP Jet Fusion 540/580

Tips for Getting Started with HP Multi Jet Fusion

Training and Certifications

HP-certified courses for machine operation and maintenance.

Partner programs through authorized resellers.

Recommended Tools and Resources

HP 3D Printing Knowledge Base

Communities: LinkedIn groups, 3D printing forums

Events: Formnext, Rapid+TCT for networking and insights.

Conclusion

HP Multi Jet Fusion sets the benchmark for high-performance polymer 3D printing, combining speed, precision, and scalability. It bridges the gap between prototyping and production, making it a key technology for industries demanding flexibility, reliability, and repeatability.

Comments