Sheet Metal Fabrication: The Ultimate Guide to Metal Forming and Manufacturing

- shiva ganesh

- Jul 30

- 4 min read

Table of Content

Introduction to Sheet Metal Fabrication

What is Sheet Metal Fabrication?

Sheet Metal Fabrication is a manufacturing process used to create components and structures from flat metal sheets. It involves techniques such as cutting, bending, punching, welding, and assembling to form functional products ranging from small brackets to large enclosures.

Commonly used metals include steel, stainless steel, aluminum, brass, and copper. This process is vital in industries like automotive, aerospace, electronics, appliances, construction, and industrial equipment.

A Brief History of Sheet Metal Work

The use of sheet metal dates back centuries, with early applications in armor and architectural elements. Modern industrial sheet metal fabrication began in the late 19th century with advancements in press brakes, stamping, and welding technologies. Today, computer-controlled equipment (CNC) ensures precision and efficiency in mass production and prototyping.

How Sheet Metal Fabrication Works

The Basic Workflow

Design the part using CAD software.

Develop a flat pattern considering bends and tolerances.

Cut the flat sheet using lasers, waterjets, or CNC punches.

Form the sheet through bending, stamping, or rolling.

Join parts via welding, riveting, or fasteners.

Finish with coating, painting, or plating as required.

Inspect for dimensional accuracy and quality.

Key Equipment in Sheet Metal Fabrication

Laser Cutters

For precise, clean cuts in a variety of materials and thicknesses.

CNC Turret Punch Press

Performs punching and nibbling operations on sheet metal.

Press Brake

Bends sheet metal to create angles, flanges, and channels.

Roll Formers

Gradually forms sheet metal into cylindrical or curved shapes.

Welding Equipment

Joins metal parts through MIG, TIG, or spot welding.

Hardware Insertion Machines

Installs nuts, studs, and fasteners.

Sheet Metal Fabrication Processes

Cutting

Laser Cutting

Plasma Cutting

Waterjet Cutting

Shearing

Forming

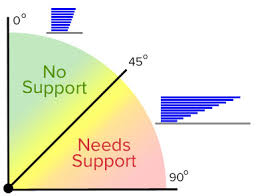

Bending

Rolling

Stamping

Deep Drawing

Joining

Welding (MIG, TIG, Spot)

Riveting

Fastening (hardware insertion)

Finishing

Powder Coating

Anodizing

Painting

Galvanizing

Materials Used in Sheet Metal Fabrication

Common Materials

Steel

Mild steel, galvanized steel, stainless steel.

Aluminum

Lightweight and corrosion-resistant.

Copper & Brass

For electrical components and decorative purposes.

Titanium

Lightweight, high strength, corrosion-resistant.

Applications of Sheet Metal Fabrication

Automotive

Body panels, brackets, chassis components, heat shields.

Aerospace

Structural components, enclosures, ducting.

Electronics

Enclosures, heat sinks, mounting brackets.

Industrial Equipment

Machine guards, conveyor systems, control panels.

Architecture

Facades, roofing, HVAC ductwork.

Appliances

Frames, panels, housings.

Advantages of Sheet Metal Fabrication

Versatility

Suitable for simple to complex parts across industries.

Strength-to-Weight Ratio

Delivers durable, lightweight solutions.

Scalability

Effective for prototypes and mass production.

Precision

CNC-controlled equipment ensures high accuracy and repeatability.

Material Efficiency

Optimizes material usage with nesting software and advanced cutting techniques.

Limitations of Sheet Metal Fabrication

Thickness Constraints

Typically limited to thin sheets (up to ~6mm).

Tooling Costs

Stamping and deep drawing require expensive tooling for mass production.

Design Restrictions

Sharp bends and small details require design considerations to prevent failure.

Surface Finish Sensitivity

Scratches and marks may require secondary finishing.

Sheet Metal Fabrication vs. Other Manufacturing Processes

Key Differences

Feature | Sheet Metal Fabrication | CNC Machining | 3D Printing |

Material | Sheet metals | Solid blocks | Plastics, metals |

Strength | High | Very High | Moderate |

Complexity | 2D/3D with bending | High complexity | Very high geometry |

Volume | Medium to high | Low to medium | Low to medium |

Speed | Fast (after setup) | Slower for large parts | Slow for production |

When to Choose Sheet Metal Fabrication

For functional, structural components with moderate complexity.

For enclosures, panels, and brackets.

When scalability and durability are key.

Future Trends in Sheet Metal Fabrication

Automation and Robotics

Robotic systems for bending, welding, and handling are streamlining production.

Advanced Materials

Increased use of high-strength steels, composites, and hybrid materials.

Smart Factories

Integration with Industry 4.0 for connected, data-driven manufacturing.

Hybrid Processes

Combining sheet metal with additive manufacturing for complex assemblies.

Cost Considerations

Machine Cost

Laser cutters, press brakes, and punches: ₹20 lakhs to ₹3 crores+.

Operational Costs

Material, tooling, labor, energy.

Secondary processes like finishing and assembly.

Part Cost

Lower per-unit cost for high volumes.

Prototypes and small batches may incur setup charges.

Choosing the Right Sheet Metal Fabrication Setup

Based on Material

Select equipment and techniques suited to steel, aluminum, copper, etc.

Based on Application

Choose processes aligned with strength, finish, and geometry requirements.

Volume Consideration

Prototypes: CNC laser cutting and bending.

Mass Production: Stamping with dedicated tooling.

Tips for Getting Started with Sheet Metal Fabrication

Design for Manufacturability (DFM)

Optimize designs to reduce waste, complexity, and costs.

Leverage Software

Use CAD tools like SolidWorks, AutoCAD, Fusion 360 with sheet metal modules.

Understand Tolerances

Account for bend allowances, spring-back, and tool limitations.

Work with Experienced Vendors

Collaborate with fabricators familiar with your industry’s standards.

Conclusion

Sheet Metal Fabrication remains a cornerstone of modern manufacturing, offering durability, scalability, and precision for countless industries. From simple brackets to complex enclosures, this process delivers efficient solutions for both prototyping and mass production.

Commentaires