Stereolithography (SLA): The Ultimate Guide to High-Precision 3D Printing

- shiva ganesh

- Jul 30

- 4 min read

Table Of Contents

Introduction to Stereolithography (SLA)

What is Stereolithography (SLA)?

A Brief History of SLA Technology

Introduction to Stereolithography (SLA)

What is Stereolithography (SLA)?

Stereolithography (SLA) is a vat photopolymerization 3D printing technology that uses a UV laser or light source to cure liquid resin layer-by-layer into solid plastic parts. SLA is widely known for producing highly detailed, accurate, and smooth-surfaced parts with complex geometries.

It is predominantly used in prototyping, dental, jewelry, medical devices, and engineering applications where precision and surface quality are critical.

A Brief History of SLA Technology

SLA was invented in 1986 by Chuck Hull, the co-founder of 3D Systems. It is recognized as the first commercially available 3D printing technology. Over the decades, SLA has advanced in speed, resolution, and material diversity, becoming a key player in precision additive manufacturing.

How Stereolithography Works

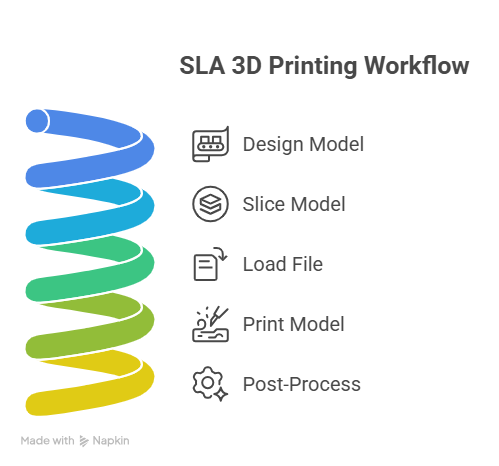

The Basic Workflow

Design the model in CAD software.

Slice the model into layers via SLA-compatible software.

Load the file into the SLA printer.

Print by curing liquid resin with a laser or light source, layer-by-layer.

Post-process the part: wash, remove supports, and UV cure.

Key Components of SLA Printers

Resin Vat / Tank

Holds the liquid photopolymer resin.

Build Platform

Supports the part as it’s lowered into or raised out of the resin.

Laser or Light Source (UV)

Cures specific areas of resin based on the model’s layers.

Control System

Manages precise laser paths, layer curing, and overall build accuracy.

Types of SLA Machines

Laser-Based SLA Printers

Use a precision UV laser to selectively cure resin layer-by-layer (e.g., Formlabs Form 3).

DLP (Digital Light Processing)

Projects an entire layer image at once using a digital light projector for faster prints.

LCD (Masked Stereolithography, MSLA)

Uses an LCD screen to mask light and cure entire layers simultaneously, ideal for desktop printers.

SLA Printing Process

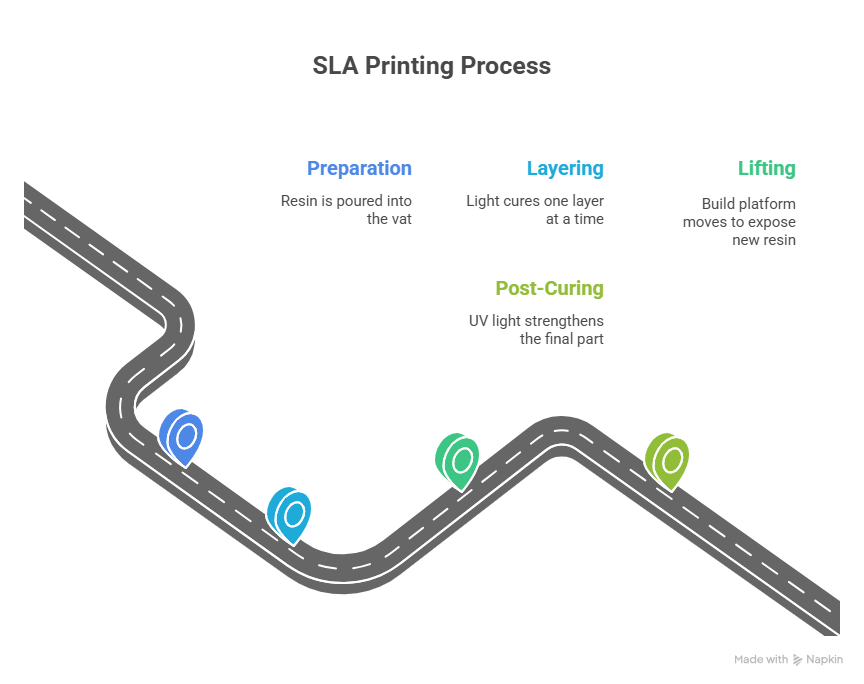

Vat Photopolymerization with Layer-by-Layer Curing

SLA creates parts by curing liquid resin where light contacts the material.

Preparation: Resin is poured into the vat.

Layering: Light cures one layer at a time.

Lifting: Build platform moves to expose new resin for the next layer.

Post-Curing: UV light strengthens the final part after printing.

Materials Used in SLA 3D Printing

Photopolymer Resins

Standard Resins

Ideal for prototypes requiring fine detail and smooth finishes.

Tough Resins

Simulate ABS-like properties for functional prototypes.

Flexible / Elastic Resins

Rubber-like materials for gaskets, seals, and flexible parts.

High-Temperature Resins

Withstand elevated temperatures for engineering applications.

Castable Resins

Used in jewelry and dental industries for investment casting.

Applications of Stereolithography

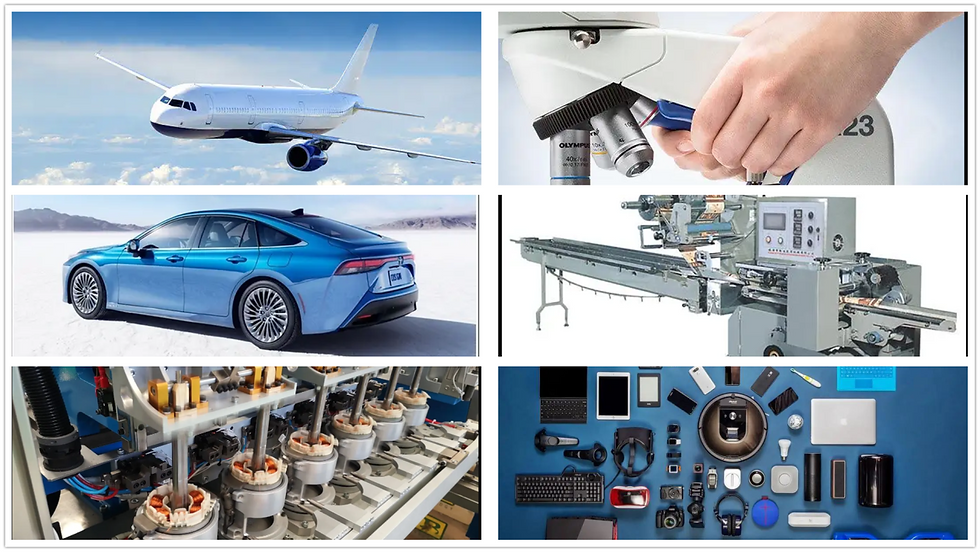

Prototyping

Highly detailed concept models, presentation pieces, and engineering prototypes.

Medical & Dental

Surgical guides, dental aligners, anatomical models, and hearing aids.

Jewelry & Fashion

Master patterns for casting, intricate designs, and molds.

Consumer Electronics

Small parts, housings, buttons, and detailed casings.

Education & Research

Detailed models for teaching, demonstration, and experiments.

Advantages of Stereolithography

Exceptional Surface Finish

Smooth surfaces with minimal layer lines compared to FDM or SLS.

High Precision and Detail

Capable of producing intricate features and tight tolerances.

Wide Range of Specialized Materials

Supports tough, flexible, high-temp, and castable resin types.

Ideal for Complex Geometries

Handles detailed designs with precision without compromising surface quality.

Limitations of Stereolithography

Material Fragility

Photopolymers are typically brittle compared to thermoplastics.

UV Sensitivity

Parts can degrade or yellow with prolonged UV exposure unless post-processed correctly.

Limited Mechanical Strength

Less suitable for high-load or structural applications.

Post-Processing Required

Mandatory washing, support removal, and UV curing after printing.

SLA vs. Other 3D Printing Technologies

Key Differences

Feature | SLA | FDM | SLS |

Process | Light-curing resin | Melting filament | Laser sintering powder |

Surface Finish | Smooth, detailed | Layer lines visible | Powdery finish |

Strength | Brittle | Moderate | Strong, durable |

Accuracy | Very high | Moderate | High |

Supports | Required | Required | Not required |

When to Choose SLA

When surface finish and detail matter most.

For prototypes, dental, jewelry, and medical applications.

For presentation models or casting patterns.

Future Trends in SLA 3D Printing

Material Advancements

More durable, biocompatible, and engineering-grade resins.

Automation & Efficiency

Automated resin handling, curing, and workflow integration.

Scalable Production

Growth of SLA in small-batch manufacturing and dental production farms.

Cost Considerations

Cost of Machines

Ranges from ₹1 lakh for desktop SLA printers to ₹50 lakhs+ for industrial systems.

Cost of Operation and Maintenance

Includes resin costs, isopropyl alcohol for cleaning, UV curing units, and replacement consumables (resin tanks, build plates).

Choosing the Right SLA Printer

Based on Material and Application

Standard: Visual prototypes

Tough / Durable: Functional models

Flexible: Elastomeric parts

Castable: Jewelry, dental casting

Based on Production Volume

Single-use / Prototyping: Desktop SLA

Batch Production / Medical: Industrial SLA with automation

Tips for Getting Started with SLA

Training and Certifications

Manufacturer certifications (Formlabs, 3D Systems)

Online courses on 3D printing fundamentals and post-processing techniques.

Recommended Tools and Resources

Communities: Reddit’s r/3Dprinting, Formlabs forums

YouTube: 3D Printing Nerd, Makers Muse

Software: PreForm, Chitubox, Lychee Slicer

Conclusion

Stereolithography (SLA) is the go-to technology for ultra-fine detail, surface quality, and precision. While it requires careful post-processing, it excels in industries demanding visual quality, accuracy, and complexity.

Comments